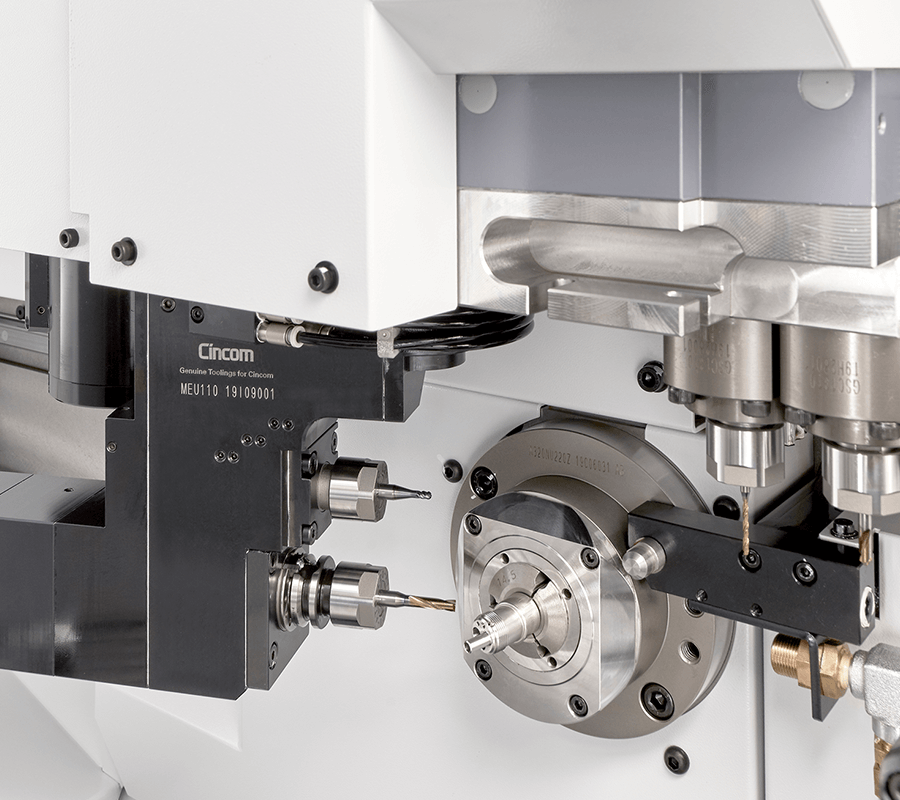

Sliding Headstock Type Automatic CNC Lathe

Cincom L20

- It realizes optimum specification for each work through the introduction of modular design. Flexibly corresponds to complex machining from simple machining

- It adopts horizontal tool layout that is one of features of L series to realize wide range of machining with variety of tools

- An optional B-axis tooling with ATC (automatic tool changer) can be equipped to the gang rotary turret. This device is not only perfect for machining medical components and other complex parts, it also supports a wide array of machining with a diverse assortment of tool variations.(L20XII ATC)