Sliding Headstock Type Automatic CNC Lathe

Cincom D25

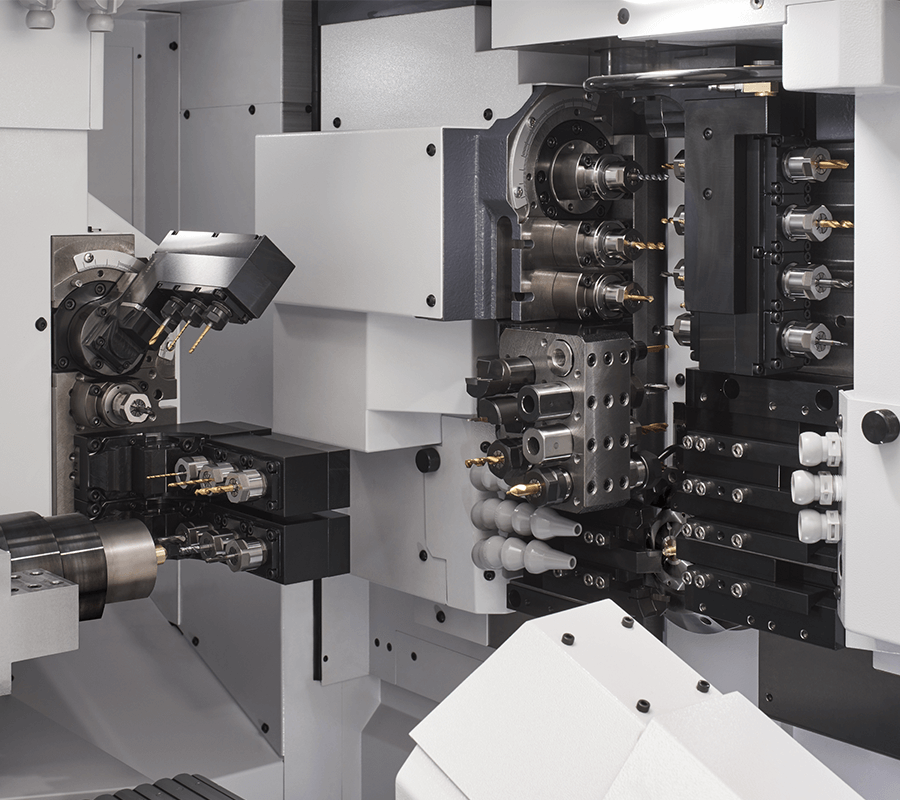

- It incorporates the B axis function on the structure with the double gang tool post, delivering both combined machining performance and high productivity.

- Maximum of 59 tools can now be mounted on the machine structure with the double gang tool post, enabling simultaneous machining and reducing the non-cutting time to achieve more productivity.

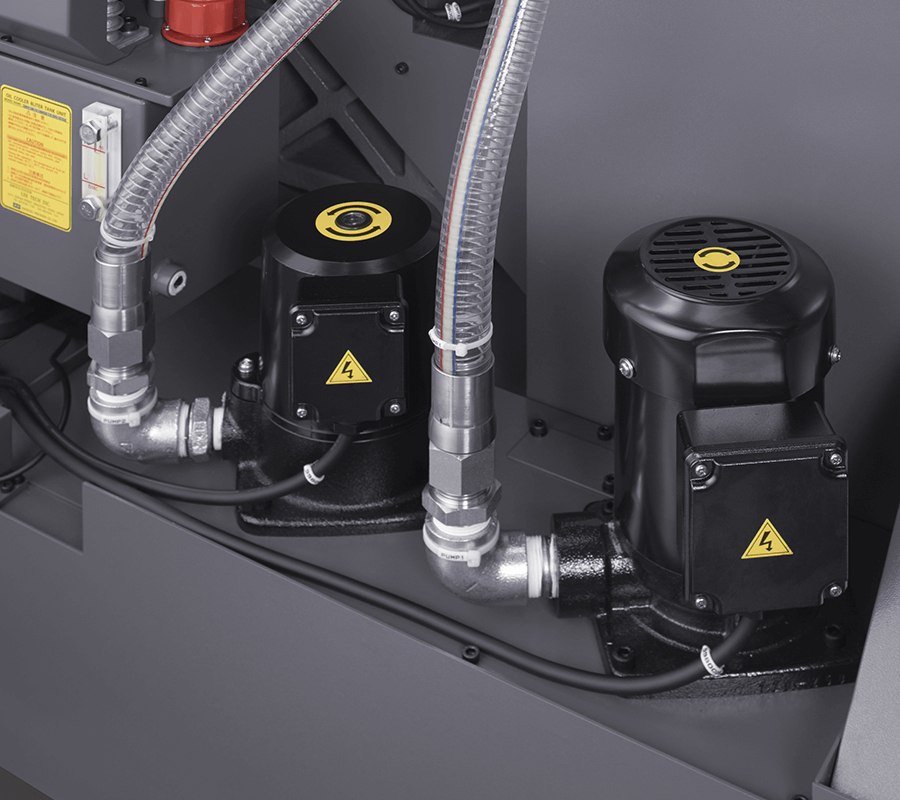

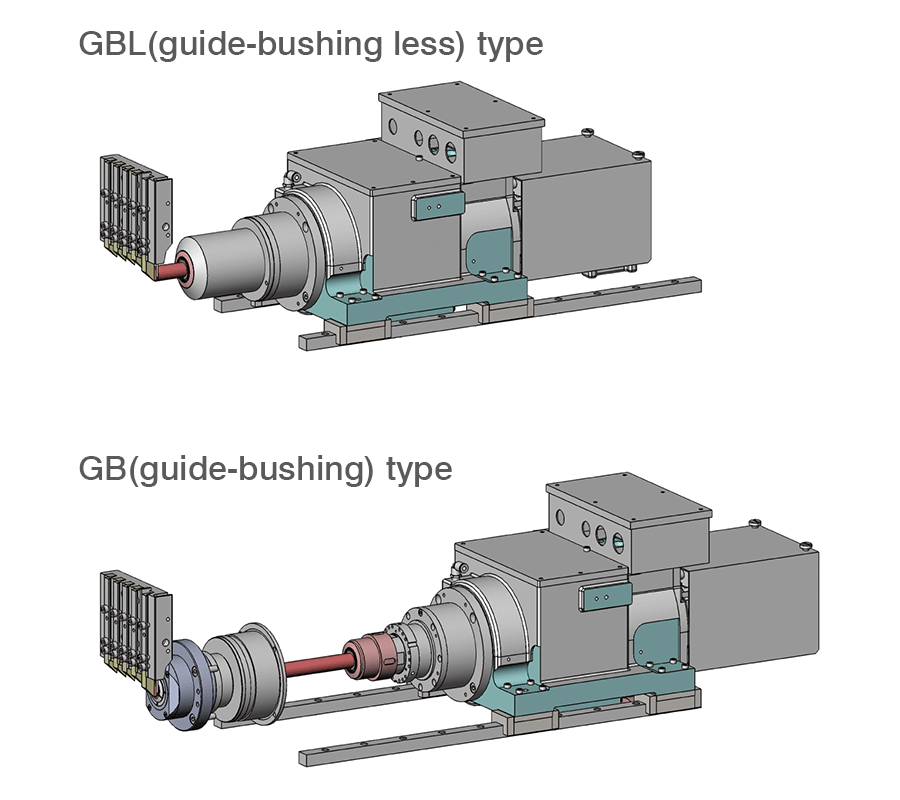

- It can hold more tools, and comes standard with superior motors, as well as functions such as switching between GB and GBL machining.