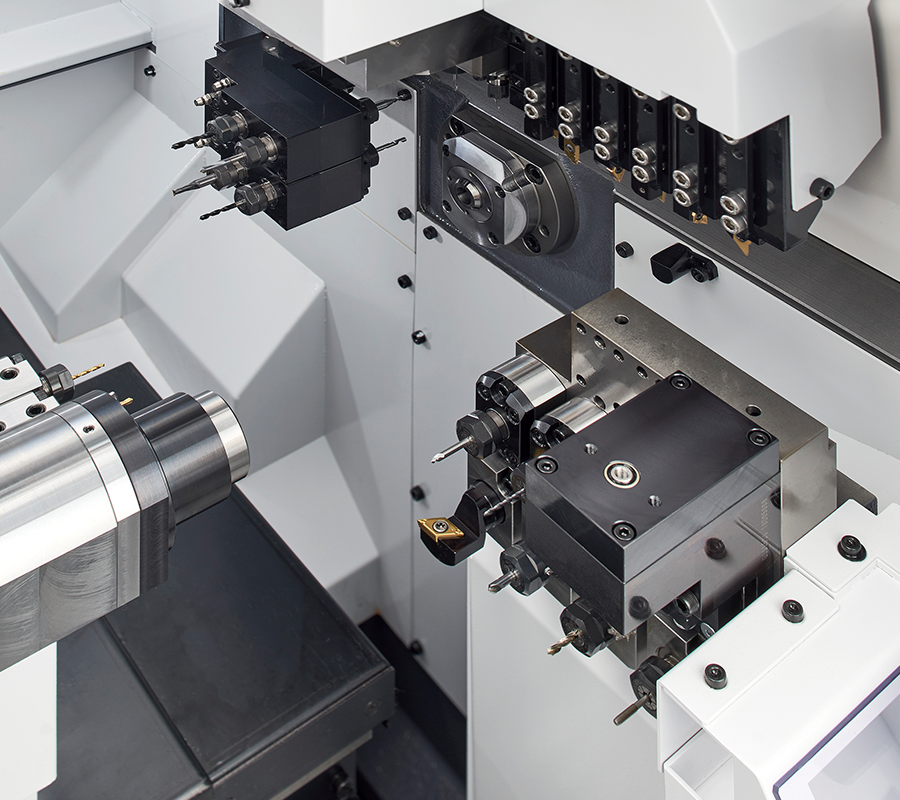

Sliding Headstock Type Automatic CNC Lathe

Cincom L12X

Introducing Citizen's newest development, the L12X with Y2 axis for even higher functionality

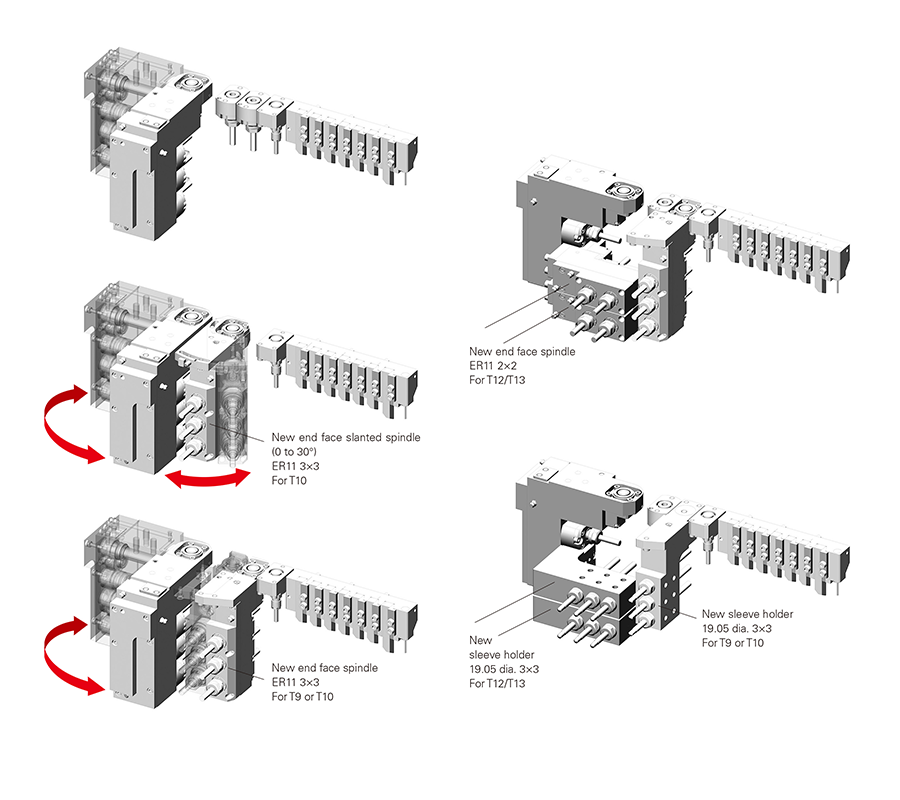

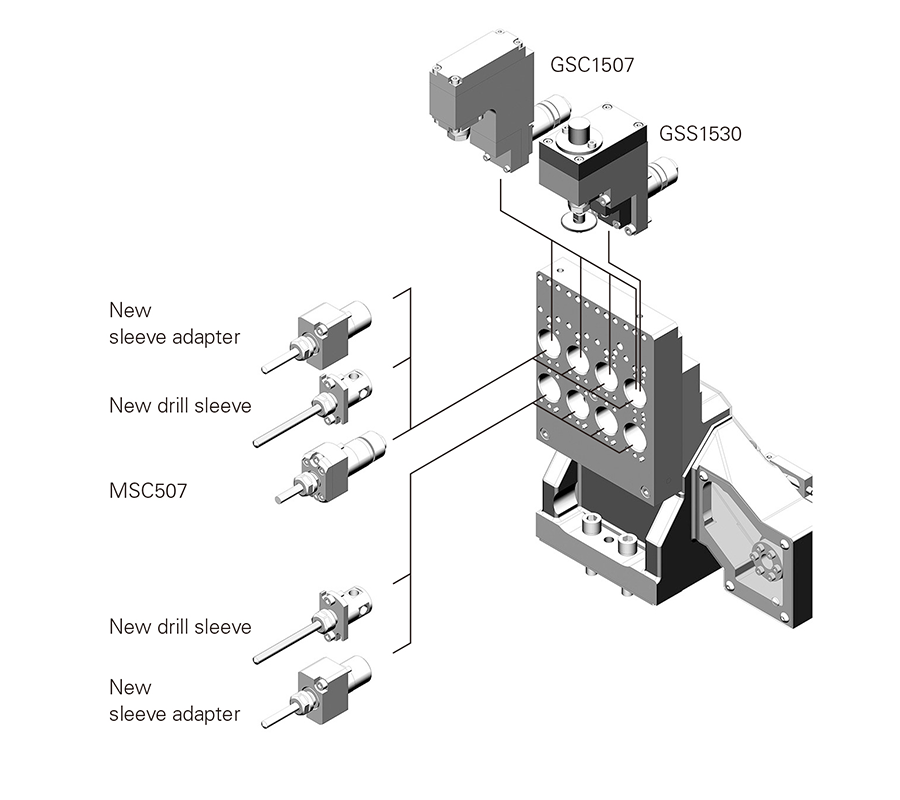

Y2 axisType X to the back spindle strengthens back machining. This increases the degree of freedom for process allocation, and increases the maximum number of tools that can be installed to 38.

- The wide variety of tooling layouts available, such as "adjustable angle end-face spindle" that allows for slanted hole drilling, enable you to perform various kinds of machining.

- Additionally, adoption of a built-in motor for the back spindle drive enables a maximum speed of 12,000 min-1.

- Citizen Machinery's patented swarf control technology, LFV. Three vibration mode (mode1, mode2, mode3) are currently available.