Multi Station Machining Cell

MC20IV

Even more evolved multi-station machining cell equipped with four modules

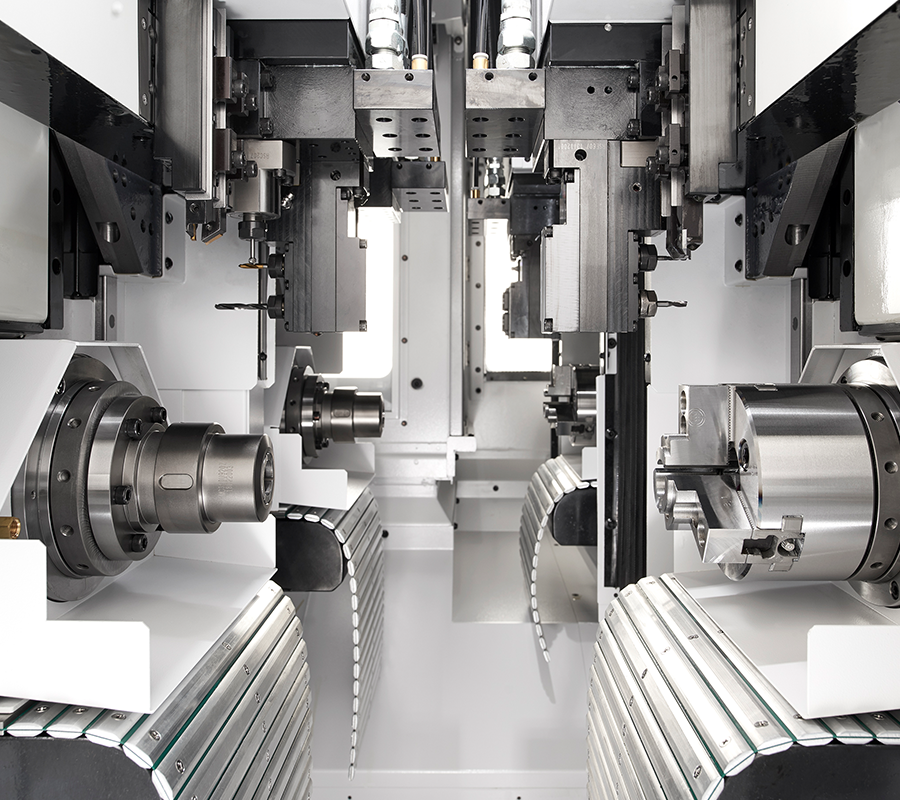

Based on the MC20 Series, this machining cell has a modular design to enable a multi-station configuration, and the four machining stations provide optimal allocation of machining processes and reduced takt time.

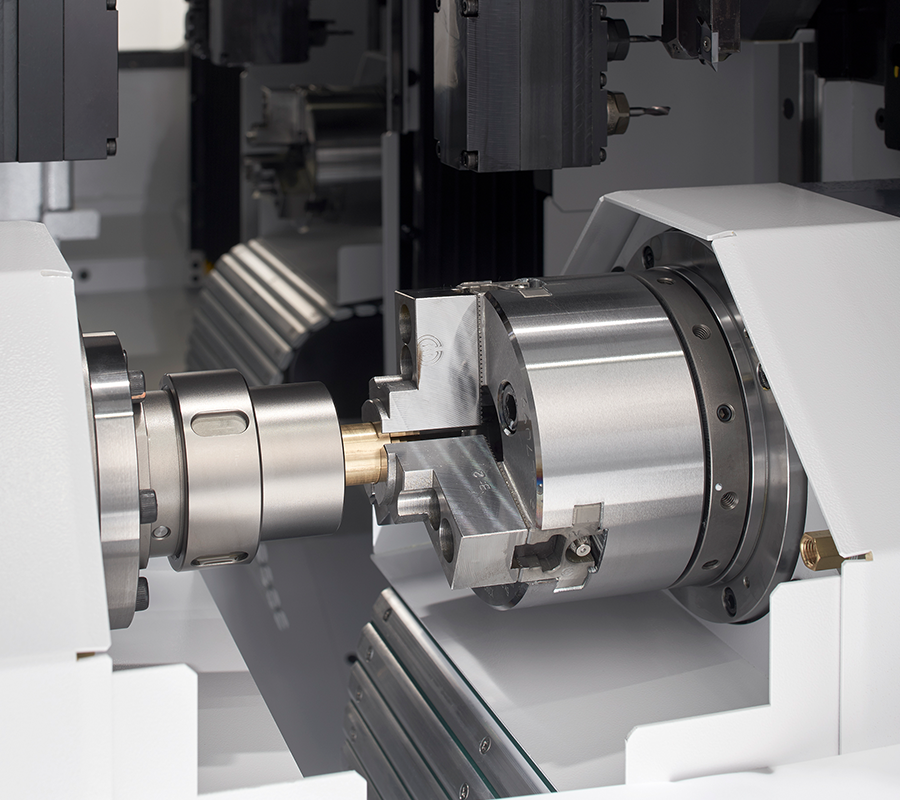

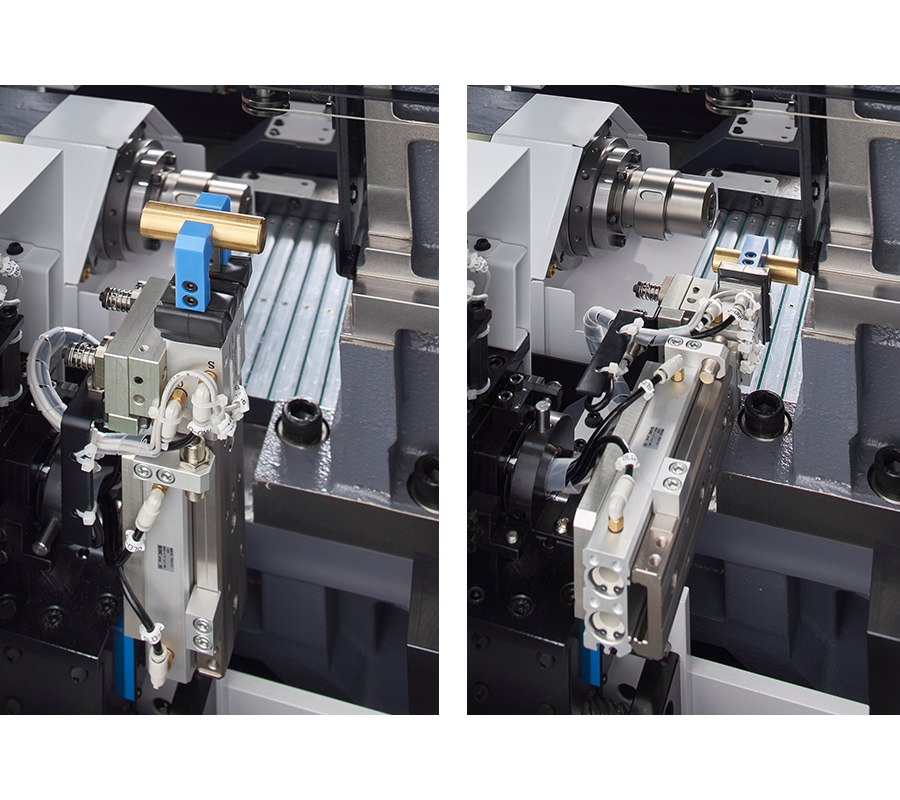

- Consisting of a headstock and tool post, the four identical machining modules have a machine configuration in which they are all located on a single head to dramatically improve per-unit area productivity in comparison with conventional production lines.

- The individual modules can be easily set up once you become familiar with handling the lathe consisting of one spindle and one tool post.