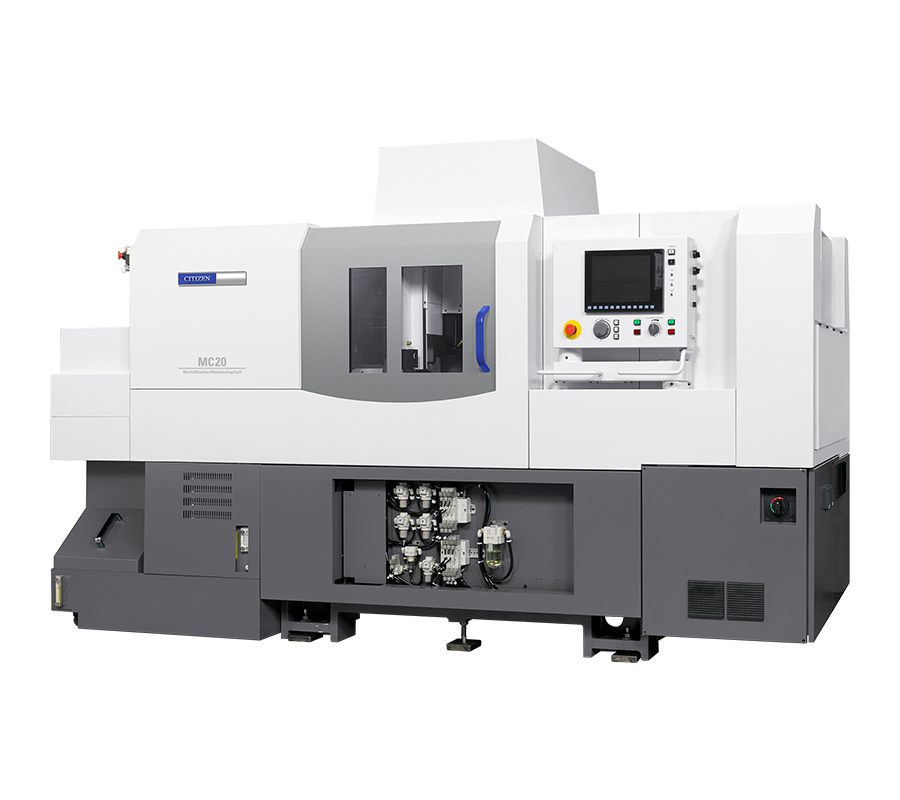

MC20III

By integrating three single-axis lathes into a single machine unit, it realizes ultra-high productivity that exceeds the limits of productivity achievable by conventional automatic lathes

By combining three machining modules in a multi-station configuration, the MC20 will support a variety of machining layouts to enable ultra-high productivity levels. Machining processes can also be optimised through the Cincom dynamic control software that supports highly flexible operations thus making 'Ko No Ryosan' (mass customization) a reality.

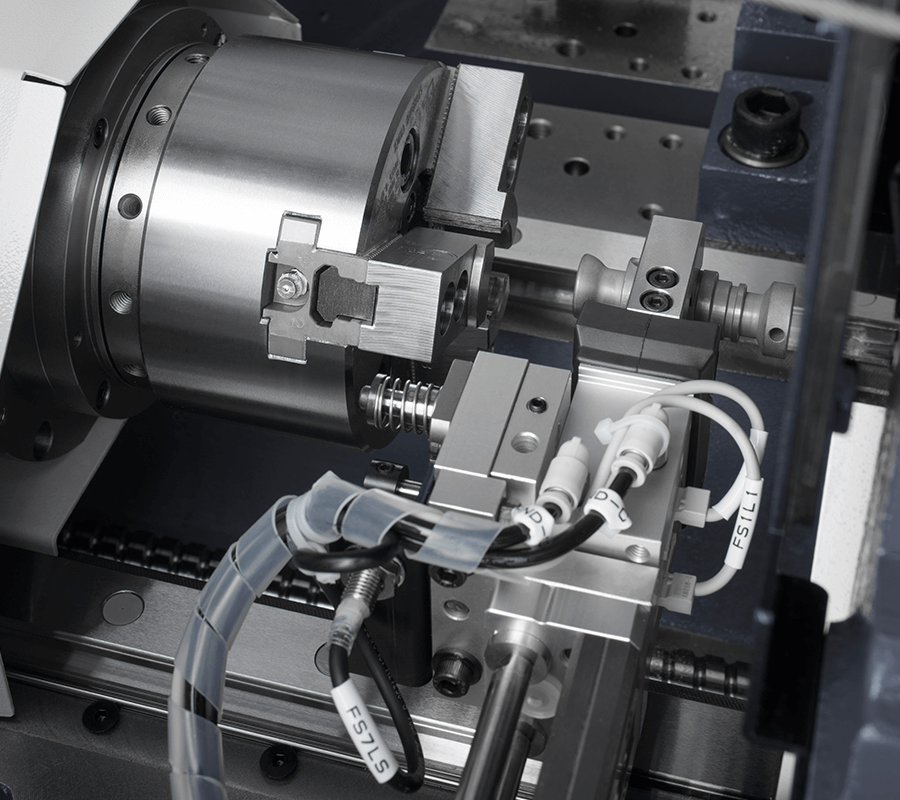

Expanded clearance between two modules helps improve working efficiency during tooling.

- Production line relocation is accomplished by moving a single machine unit, and production line setup changes are achieved by changing the setup on a single machine

- By combining various types of modules not restricted those for turning operations, it evolves further with versatile functionality