About LFV

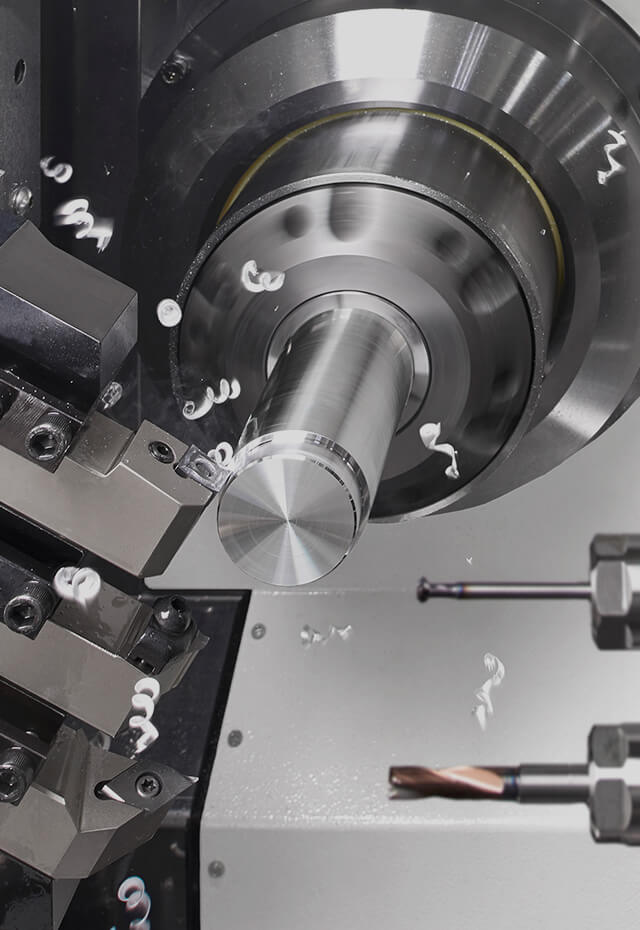

LFV technology stands for low frequency vibration cutting.

The servo axes are vibrated in the axial direction using

a unigue control technology where by cutting is performed while synchronising

this vibration with the rotation of the spindle.

This cutting method introduces regular "air-cutting" into the cycle,

breaking up of chips into very small pieces making it the optimum processing method

for difficult-to-machine materials.

- Which materials is LFV best suited for?

- Inconel alloy, titanium, stainless steel, iron, copper, nylon, plastic, and more.

Features

1A variety of types of machining can be handled

- Z axis direction

- X axis direction

- Taper

- Arc

- Drilling

- Threading

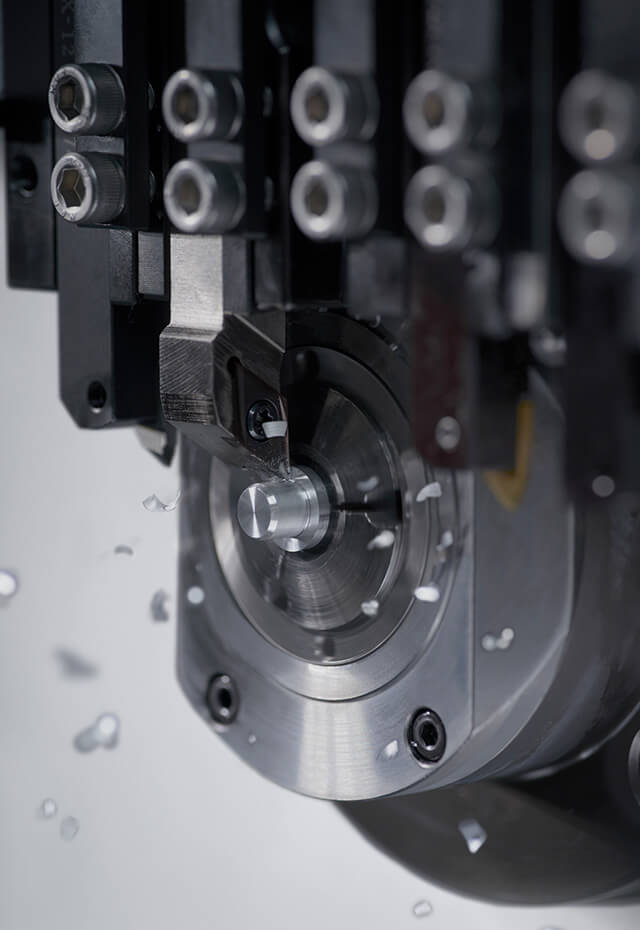

Finely fragmented chips are discharged smoothly along the flutes in the drill, greatly reducing the number of steps required.

LFV makes it possible.

2Three vibration modes

- Mode 1Designate the number of vibrations per workpiece rotation

- When fine swarf fragments are required

- Mode 2Designate the amount of workpiece rotation per vibration

- When high peripheral speed is required for fine machining or deep, small-diameter holes

- Mode 3Processing method which alters the vibration timing within the threading pass

- When breaking up chips during threading processing is desired

Benefits

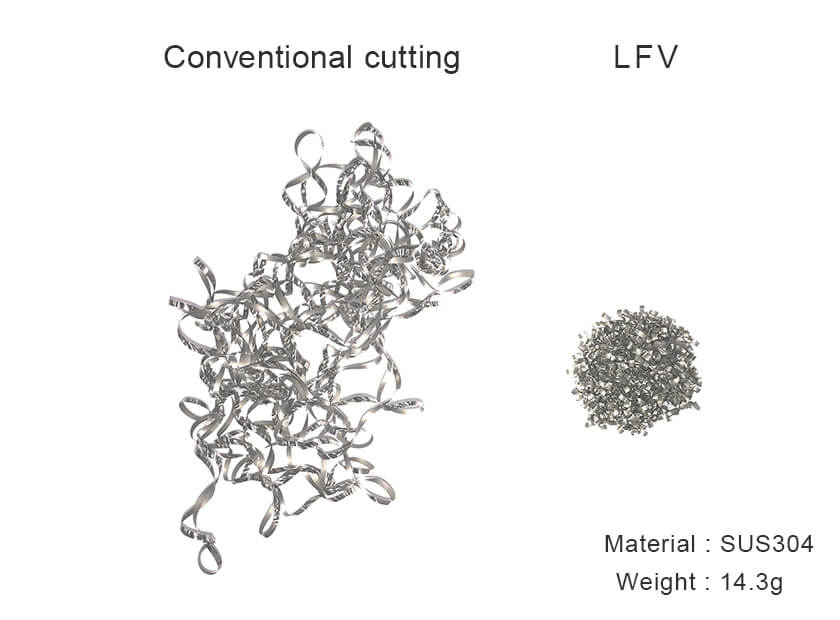

- Conventional cuttin

- LFV

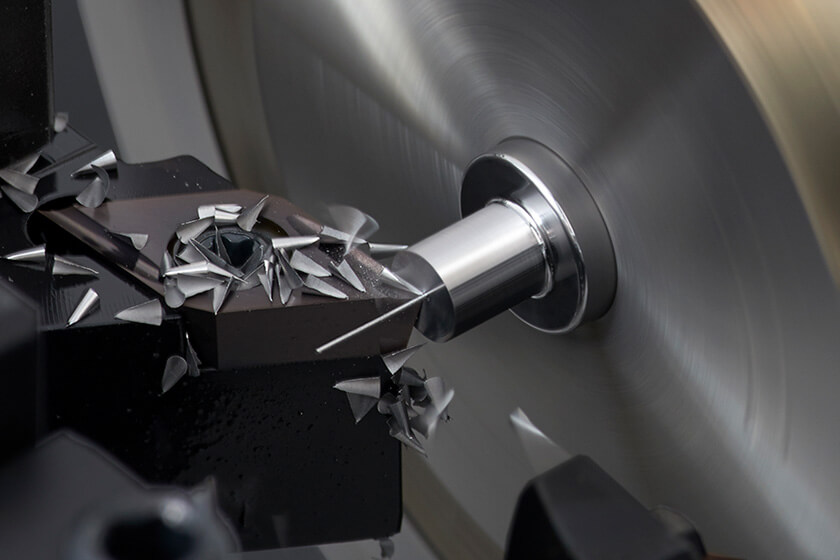

- Minimizes defects and tool damage caused by chips

- Keeps machining costs low

- Greatly reduces machining downtime due to chip removal

- Less need to monitor machining processes means

more unmanned mass production operations

-

Chip comparison

- Remove chips far less frequently

User feedback

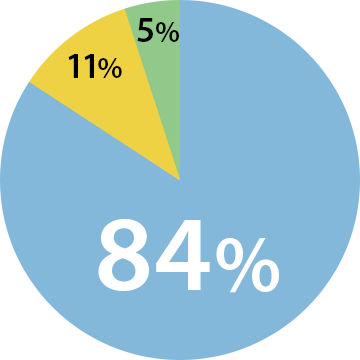

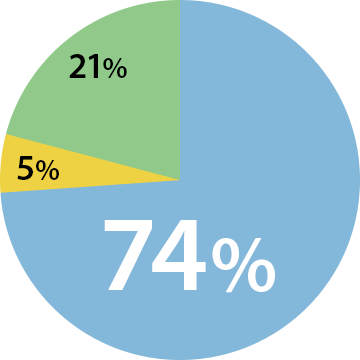

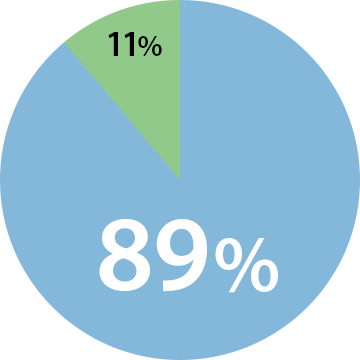

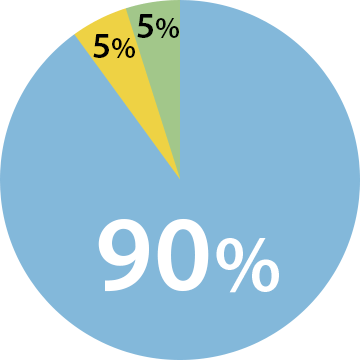

Q.1Did LFV sufficiently break up of chips?

- Sufficient fragmentation

- Greatly reduced entanglement

Q.2Did LFV result in fewer momentary stoppages?

- No longer a need to check for swarf entanglement

- No change in the number of momentary stoppages

- No momentary stoppages to begin with

Q.3Was the volume of chips reduced?

- By 50-90%

- No real change in collection frequency

- Not sure due to the use of a chip conveyor

Q.4Are you satisfied with the LFV?

- More reliable production quality

- Takes some getting used to, but very effective

- Getting used to having LFV may actually cause problems

- We'd like to extend tool life a bit more

Q.5Will you continue to purchase LFV?

- It is effective for unmanned operations

- Drastically reduces swarf-related problems

- We don't need it on every machine

- Depends on what it will cost

Want proof of this positive customer feedback?

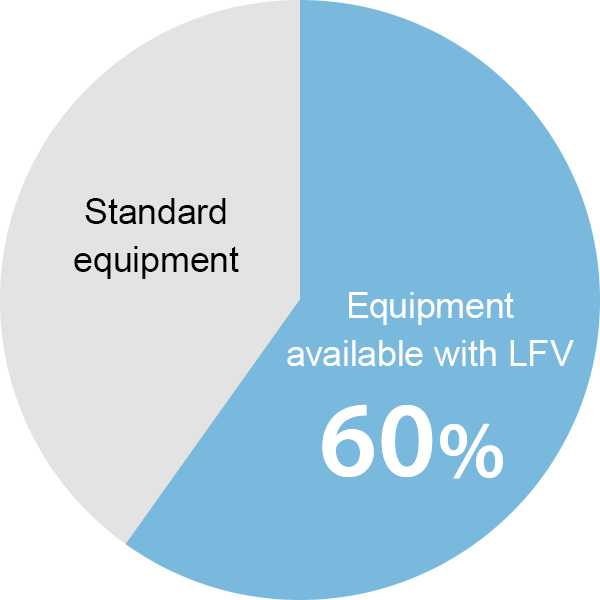

About 60% of the L20s purchased in Japan

are ordered with LFV !

Equipment available

with LFV

with LFV

Opening up new possibilities in machining technology with low frequency vibration cutting

The VC03 is Citizen's first machining tool to come equipped with LFV, opening up new possibilities in machining technology. Its compact, space-saving design shortens production lines, while an accuracy-boosting machine configuration carried over from the GN series delivers incredible precision.

Built with a modular design versatile enough for modern manufacturing

The L20 is our best-selling Cinecom machine and comes in four different models, ranging from a 5-axis machine with excellent cost performance to a high-end machine equipped with B axis and a back spindle Y axis. LFV is available as an optional feature to further expand your machining possibilities.

MORE

Detachable guide bushing comes standard to handle all small-diameter work with 5-axis control

The detachable guide bushing can be fitted or removed quickly and simply, making it possible to do processing work that once took two machines to accomplish. The L12 does it all. Equipped with a 15,000 min-1 high-speed spindle, 10,000 min-1 rotary tools, and optional LFV, you're ready to take on nearly any type of small-diameter machining tasks.

MORE(L12VII) MORE(L12X)

Integrated machining modules for multi-spindle machining makes the MC20 ready to handle all kinds of process layouts

The MC20 is made up of three machining modules, integrating three single-axis lathes into one machine unit. Customized settings for workpiece IN/OUT and paths help you achieve ideal process distribution and workflow. And of course, all of the modules come with the option of LFV.

MORE(MC20III) MORE(MC20IV)

Turret and gang tool post open up rich array of machining possibilities

Innovative structure gives you all the versatility of a turret plus the high speed of a gang tool post, making it possible to mount up to 43 tools. Three-system configuration allows simultaneous machining with up to three tools. Add the option of LFV for a rich array of machining possibilities.

MORE

The L32 features a versatile modular design capable of handling diameters up to 32 millimeters-the largest in the L Series

The L32 is available in four different models, each with a modular design. The IX and XII models are equipped with a B axis on the gang tool post rotary tool, making it possible to machine angled holes from multiple different angles or simultaneously control contouring along four axes. Add optional LFV to drastically reduce swarf-related issues.

MORE

Extensive tooling including a double gang tool post and optimal process layout deliver high productivity

"Simultaneous machining with three tools" including additional machining with a back tool on the independent back tool post, in addition to simultaneous machining with two tools on the front face with the double tool post, allows simultaneously machining with turning, drilling, milling and so on, shortening cutting time and achieving high productivity.

MORE

The next evolution in 5-axis lathes, delivering improvements in both functionality and cost

While being an entry-level machine with excellent cost performance, its LFV mode 1 capability has further increased its range of processing potential.

MORE

Cincom's flagship model, whose gang tool and turret features enable complex machining

LFV is now featured in the M32, which is capable of complex machining by bringing together the features of the B axis spindle VIII model delivering contouring through its 5-axis control and the adjustable-angle spindle VII and VIII models in combination with the Y axis.The Cincom M32 alleviates chip-related issues not only when processing linear surfaces, but also in a wide range of other situations such as tapered, circular, drilling, and internal threading processing.

MORE

Innovative Turret Lathe ANX Opens Up a New Era

Now a turret lathe from Miyano brand is equipped with LFV technology for the first time. This solves the problem of chip entanglement that had persisted for many years.

MORE

Cincom’s best-selling L series machines have been relaunched with exciting new functions

The L20 XIIB5 finally enables simultaneous 5-axis control, greatly expanding the machining range of CNC automatic lathes. Improved basic performance, along with great advances in ease of use.

MORE

LFV Technology with Hand Scraped Slideways for the First Time

This headstock type CNC automatic lathe is a best-selling machine which, despite its compact size, has a highly rigid base and turret with a 2-spindle/1-turret configuration enabling complex machining. And equipping hand scraped slideways with LFV technology for the first time helps customers achieve more stable production.

MOREContact

We're happy to answer your questions and share more about our products and technologies.

Feel free to contact us by phone or via our online contact form.