"Cincom D25" Added to the Lineup of LFV Technology-Capable Models

- Seven Models Now Feature LFV Technology -

Citizen Machinery Co., Ltd.

Citizen Machinery Co., Ltd. (headquarters: Miyota-machi, Kitasaku-gun, Nagano Prefecture, President: Keiichi Nakajima) announced today that in August it will launch an LFV (low frequency vibration cutting; hereafter "LFV technology*")-capable model of its "Cincom D25," which has been on sale since spring 2017.

LFV technology enables high-precision machining over an extended period. Since Citizen Machinery launched the first LFV model in 2013, it has rolled out the technology to products across both of the "Cincom" and "Miyano" brands.

Citizen Machinery is pleased to announce that LFV technology will now be available in the "Cincom D25," which has been on sale since spring 2017. The "D25" features combined machining of medium-diameter materials with a maximum machining diameter of 25mm. Particularly in complex machining, resolution of issues relating to swarf becomes critical, and the addition of LFV technology (which finely fragments swarf) to the "D25" has been highly anticipated.

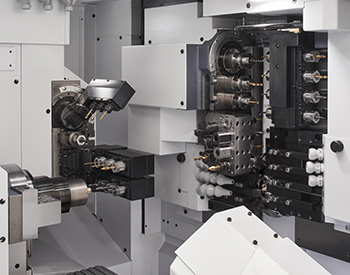

Cincom D25

An LFV technology-capable model of Citizen Machinery's mainstay "Cincom L20" was launched in 2016, and currently, over half of the Japanese domestic shipments of the "L20" are models including LFV. This technology has been highly rated, to the extent that many customers currently using LFV have requested continued launch of models featuring the LFV technology.

Citizen Machinery has also introduced the LFV Engineer and LFV Meister accreditation systems to provide machining advice etc. and enable customers to use LFV technology with greater peace of mind. In addition, Citizen Machinery is taking proactive initiatives to promote both the advancement in LFV technology and greater engagement within the LFV community. These initiatives include hosting technical forums to overcome technical issues faced, hear requests first-hand, and exchange information with customers using LFV technology.

With the addition of the "D25" to the LFV range, a total of seven models now feature LFV technology. In order to resolve the wide range of issues faced by customers relating to swarf, Citizen Machinery will - focusing on its core models - continue to expand its lineup of products including LFV technology.

LFV technology

Using Citizen's unique control technology, the servo axes are vibrated in the axial direction, introducing regular "air-cutting" (where the cutting tool is not making contact with the materials being machined) into the cycle, breaking up swarf into very small pieces. LFV technology increases efficiency when machining deep, small-diameter holes, and also finely fragments swarf of difficult-to-machine materials, where swarf pieces tend to become elongated. This advancement achieves resolution of a wide range of issues relating to swarf, which have been of concern for many years in cutting work. In addition, LFV technology enables high-precision machining over an extended period by drastically reducing the volume of swarf generated and preventing damage to the surface of the workpiece.

Difference in shape of the same weight of swarf

(Material: SUS304)

Left: Swarf from conventional cutting

Right: Swarf from LFV

- *

- LFV is a registered trademark of Citizen Watch Co., Ltd.

Reference Materials: About the "Cincom D25"

By utilizing a double gang tool post for the tool post layout used in front machining, the "Cincom D25" not only enables simultaneous machining and increasing the number of tools held, but also increases productivity through reducing tool selection time to almost zero.

Main Features of the "D25"

1. Incorporates the B axis function into the gang tool post, enabling diagonal hole machining (VIII model only)

Includes the B axis function, usable in front/back machining. While naturally handling a range of diagonal hole machining such as helical complementary machining and multiple angles of diagonal hole machining, the simultaneous five axis control (three orthogonal axes and two rotational axes) enables machining of even more complex shapes.

Cincom D25

2. Enhanced back tool post

A maximum of 28 back machining tools can be mounted. Utilizing an independent back tool post enables enhanced diagonal hole machining etc., and also enables optimal front/back machining process division.

The "D25" features combined machining performance not affected by being front or back, flexibly adapting to any complex machining. The excellent simultaneous machining performance delivers high productivity.

3. Thorough standard equipment supporting combined machining and high productivity

The spindle and rotary tool motors feature large diameter-class performance, delivering increased productivity. The standard equipment spindle specification enables switching between guide-bushing and guide-bushing-less types, reducing customers' total running costs. Careful consideration is given to usability, such as in the fitting of a lift-type cutting chamber door, which enables easier worker operations and provides an expansive and open work space.

| Item | D25VII | D25VIII | |

|---|---|---|---|

| Maximum machining diameter | ø25mm | ||

| Maximum machining length | Guide-bushing | 250mm | |

| Guide-bushing-less | 2.5D | ||

| Maximum drilling diameter for main spindle | ø12mm | ||

| Maximum front tapping diameter (Cut tap) | M10 | ||

| Spindle speed | Max.10,000min-1 | ||

| Maximum drilling diameter for rotary tool | ø10mm | ||

| Maximum tapping diameter for gang rotary tool (Cut tap) | M8 | ||

| Spindle speed of the gang rotary tool | Max.9,000min-1 | ||

| Maximum chuck diameter of back spindle | ø25mm | ||

| Maximum protrusion length of the back spindle workpiece | 50mm | ||

| Maximum drilling diameter in back machining process | ø12mm | ||

| Maximum tapping diameter in back machining process | M10 | ||

| Back spindle speed | Max.10,000min-1 | ||

| Number of tools to be mounted | 59 | 43 | |

| Tool size | Turning tool | □16mm/□19mm | |

| Sleeve | ø25.4mm | ||

| Motors | For spindle drive | 3.7/5.5kW | |

| For tool spindle drive | 2.2kW | ||

| For back spindle drive | 2.2/3.7kW | ||

| For driving rotary tools on the back tool post | 1.0kW | ||

| Weight | 3,450kg | ||

- Maximum machining diameter

- ø25mm

- Maximum machining length【Guide-bushing】

- 250mm

- Maximum machining length【Guide-bushing-less】

- 2.5D

- Maximum drilling diameter for main spindle

- ø12mm

- Maximum front tapping diameter (Cut tap)

- M10

- Spindle speed

- Max.10,000min-1

- Maximum drilling diameter for rotary tool

- ø10mm

- Maximum tapping diameter for gang rotary tool (Cut tap)

- M8

- Spindle speed of the gang rotary tool

- Max.9,000min-1

- Maximum chuck diameter of back spindle

- ø25mm

- Maximum protrusion length of the back spindle workpiece

- 50mm

- Maximum drilling diameter in back machining process

- ø12mm

- Maximum tapping diameter in back machining process

- M10

- Back spindle speed

- Max.10,000min-1

- Number of tools to be mounted

- 59

- Tool size【Turning tool】

- □16mm/□19mm

- Tool size【Sleeve】

- ø25.4mm

- Motors【For spindle drive】

- 3.7/5.5kW

- Motors【For tool spindle drive】

- 2.2kW

- Motors【For back spindle drive】

- 2.2/3.7kW

- Motors【For driving rotary tools on the back tool post】

- 1.0kW

- Weight

- 3,450kg

- Maximum machining diameter

- ø25mm

- Maximum machining length【Guide-bushing】

- 250mm

- Maximum machining length【Guide-bushing-less】

- 2.5D

- Maximum drilling diameter for main spindle

- ø12mm

- Maximum front tapping diameter (Cut tap)

- M10

- Spindle speed

- Max.10,000min-1

- Maximum drilling diameter for rotary tool

- ø10mm

- Maximum tapping diameter for gang rotary tool (Cut tap)

- M8

- Spindle speed of the gang rotary tool

- Max.9,000min-1

- Maximum chuck diameter of back spindle

- ø25mm

- Maximum protrusion length of the back spindle workpiece

- 50mm

- Maximum drilling diameter in back machining process

- ø12mm

- Maximum tapping diameter in back machining process

- M10

- Back spindle speed

- Max.10,000min-1

- Number of tools to be mounted

- 43

- Tool size【Turning tool】

- □16mm/□19mm

- Tool size【Sleeve】

- ø25.4mm

- Motors【For spindle drive】

- 3.7/5.5kW

- Motors【For tool spindle drive】

- 2.2kW

- Motors【For back spindle drive】

- 2.2/3.7kW

- Motors【For driving rotary tools on the back tool post】

- 1.0kW

- Weight

- 3,450kg

Typical machining workpieces

Medical device components, automotive components, hydraulic and pneumatic equipment components, etc.