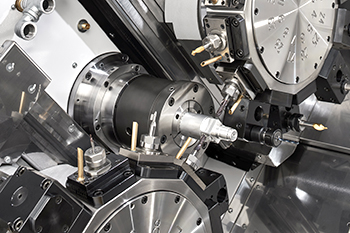

- First to be equipped with "LFV technology" on the turret tool post -

A new series for the first time in 4 years

The Miyano "ANX42SYY" enables combined machining, micromachining, and superimposition control!

Citizen Machinery Co., Ltd.

Citizen Machinery Co., Ltd. (Headquarters: Miyota-machi, Kitasaku-gun, Nagano-ken, President: Keiichi Nakajima) will release the new Miyano fixed headstock CNC automatic lathe "ANX42SYY" series.

As a first, which has been highly anticipated by many of our customers, we have incorporated LFV technology on the turret tool post, to develop the unit as a global strategic machine capable of medium-diameter complex machining.

The new Miyano "ANX42SYY" series, which is the first in four years, is a 2-spindle, 2-turret bar material processing machine equipped with spindles with maximum processing diameter of φ42 mm, capable of simultaneous processing of the front and back spindles. The turret tool post is equipped with the Low-frequency Vibration Cutting technology (hereinafter referred to as LFV technology) for the first time. In addition, the "built-in spindle motor" method is used for both the front and back spindles, and linear guides are mounted on all slide axes improving response and fast forward speed. The superimposition control *1 is also a welcome addition that enables simultaneous machining with a higher degree of freedom contributing to shorter cycle times. Furthermore, by mounting the Y-axis on both the upper and lower turrets, combined machining and micromachining are also possible.

The unit also comes with a newly developed new HMI (Human Machine Interface) control panel. By improving the arrangement of each device in the casting structure optimized through structural analysis, comes a compact machine that takes into consideration operability and usability, including 20% space saving compared to existing products.

Through these types of functional improvements, we will further develop new fields in the medical arena, in addition to the automobile, pneumatic, and hydraulic systems that Miyano already specializes in.

- ※1

- Superimposition control:Simultaneous processing of other systems in conjunction with one system. When machining the front and back spindles at the same time with the blades on one turret, the movement level required for machining the back spindle is automatically calculated while considering the movement of the turret for machining the front spindle. Machining control is performed in accordance with each program.

Main features

1.First to be equipped with LFV technology on the turret tool post

Highly anticipated by the market, we have achieved the first model to install LFV technology in the turret tool post. This will help to contribute to solving various customer issues related to chips. Through the installation on this machine, there will be 10 models equipped with LFV.

2.Cycle times are greatly reduced

A "Built-in spindle motor" is adopted for the front and back spindles. The response speed has been improved by 30% compared to machine types equipped with belt-driven spindles. In addition, the adoption of a linear guide improves the fast-forward speed, and the superimposition control that enables simultaneous machining shortens the cycle time.

The chuck that picks up the material is compatible with both the front and back spindles of φ42 mm, improving the degree of processing versatility.

3.Mounting Y-axis on turrets

By mounting the Y-axis on the upper and lower turrets, the number of operating axes increases, enabling greater complex machining and expanding the machining range.

4.Achieves 20% space saving as well as giving greater consideration to operators

Equipped with the latest NC, a 15-inch touch panel is used for the control panel equipped with the new HMI (Human Machine Interface), and operation compatibility is provided so that not only Miyano but also Cincom brand users can use it with ease, improving machine operability. The cutting room is equipped with a large sliding door to ensure a wider open work space and visibility that allows you to check the machining status. This is a compact machine that takes into operability and usability into consideration while saving about 20% of the space compared to existing models.

Main machining work

Automobile-related parts, hydraulic/pneumatic instrument parts, and medical instrument parts

Reference: LFV technology

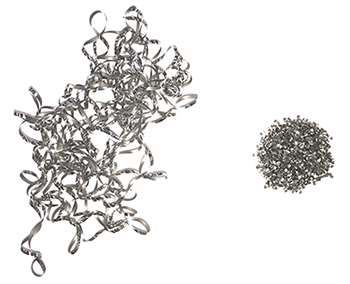

LFV technology is a unique Citizen control technology which breaks up the chips by vibrating the servo axis in the cutting direction and providing “air-cutting” time where the tool does not touch the material. As a result, this achieves solutions to various issues regarding chips, which has been a challenge for many years in the cutting process, such as improvements in the efficiency of small-diameter, deep-hole machining and fine cutting of chips produced when working with difficult-to-cut materials where the resulting chips have tended to be quite long. In addition, this technology achieves machining with high precision for an extended period of time by dramatically reducing the chip volume and preventing defects on the workpiece surface.

■ Differences in the shape of chips with the same weight

(material: SUS304)

Left: chips from conventional cutting

Right: chips from LFV technology

- ※

- LFV is a registered trademark of Citizen Watch Co., Ltd.

Machine Specifications

| Item | ANX42SYY | |

|---|---|---|

| Maximum Machining Diameter | ø42mm | |

| Maximum Machining Length | 130mm | |

| Spindle Speed | Max.6,000min-1 | |

| Maximum chuck diameter of back spindle | ø42mm | |

| Back spindle speed | Max.6,000min-1 | |

| Slide Stroke (Stroke) |

X1 axis | 140mm |

| Y1 axis | 70mm(+35m/-35mm) | |

| Z1 axis | 315mm | |

| X2 axis | 140mm | |

| Y2 axis | 70mm(+35m/-35mm) | |

| Z2 axis | 430mm | |

| X3 axis | 240mm(+120m/-120mm) | |

| Z3 axis | 440mm | |

| Number of Tool Mounting Faces |

Upper Turret | 12 |

| Lower Turret | 12 | |

| Tool Size | Turning tool | □20mm |

| Sleeve | ø25mm | |

| Motors | For Spindle Drive | 11/7.5kW |

| For Back Spindle Drive | 11/7.5kW | |

| For Upper Turret Tool Spindle Drive | 2.2kW | |

| For Lower Turret Rotary Tool Drive | 2.2kW | |

| Machine Weight | 6,200kg | |

- Maximum Machining Diameter

- ø42mm

- Maximum Machining Length

- 130mm

- Spindle Speed

- Max.6,000min-1

- Maximum chuck diameter of back spindle

- ø42mm

- Back spindle speed

- Max.6,000min-1

- Slide Stroke(Stroke) [X1 axis]

- 140mm

- Slide Stroke(Stroke) [Y1 axis]

- 70mm(+35mm/-35mm)

- Slide Stroke(Stroke) [Z1 axis]

- 315mm

- Slide Stroke(Stroke) [X2 axis]

- 140mm

- Slide Stroke(Stroke) [Y2 axis]

- 70mm(+35mm/-35mm)

- Slide Stroke(Stroke) [Z2 axis]

- 430mm

- Slide Stroke(Stroke) [X3 axis]

- 240mm(+120mm/-120mm)

- Slide Stroke(Stroke) [Z3 axis]

- 440mm

- Number of Tool Mounting Faces [Upper Turret]

- 12

- Number of Tool Mounting Faces [Lower Turret]

- 12

- Tool Size [Turning tool]

- □20mm

- Tool Size [Sleeve]

- ø25mm

- Motors [For Spindle Drive]

- 11/7.5kW

- Motors [For Back Spindle Drive]

- 11/7.5kW

- Motors [For Upper Turret Tool Spindle Drive]

- 2.2kW

- Motors [For Lower Turret Rotary Tool Drive]

- 2.2kW

- Machine Weight

- 6,200kg