Two Models Added to Cincom "L12" Series

- Enhanced productivity and combined machining performance through substantial increase in mounted tools -

Citizen Machinery Co., Ltd.

Citizen Machinery Co., Ltd. (Headquarters: Miyota-machi, Kitasaku-gun, Nagano-ken, President: Keiichi Nakajima) has substantially increased the number of mounted tools on its Cincom "L12" small-scale precision sliding headstock type CNC automatic lathes with "VIII" and "X" models.

The new "L12 X" high-end equipment will be exhibited at "JIMTOF2018" in Tokyo Big Sight starting on November 1.

The well-established L series is sold worldwide as versatile machines used in metal processing in various industries, including precision equipment parts, medical parts, and automobile parts. Since the series was released in 1986, the cumulative shipments have exceeded 20,000 units.

We have expanded the line-up with this addition of two machines to the "L12" series which is renowned for small diameter machining with a maximum of ø12mm.

By adopting several modular tooling combinations that allow for selecting functionality to suit a variety of machining needs, and adding the Y2 axis to the back spindle in the X type, the maximum number of mounted tools has been greatly increased (VIII and X can mount 34 and 38 tools respectively, while the VII can mount 28).

In addition, by increasing the back spindle speed and improving the flexibility of allocating machining steps, we have enhanced productivity and combined/complex machining performance.

Main Features

1. Significant increase in the number of mounted tools, enabling up to 38 tools to be installed

Keeping with the horizontal tool layout allowing for a large number of tools (turning tools and drills) to be mounted and restricting interference between them, which is a feature of the L series, the maximum number of tools that can be installed has increased to 38 (X type only: 28 and 34 for existing VII and VIII types respectively) due to adding Y2 axis to the back spindle (X type only), and so on.

In addition, with a wide range of rotating tools, a variety of combined/complex machining can be dealt with, such as an "Angle-adjustable end face spindle" capable of drilling to the eccentric position of the end face of a workpiece, a "Slitting spindle" which produces slots in the ends of a workpiece such as the head of the minus screw, and "Thread whirling" to create bolt threads.

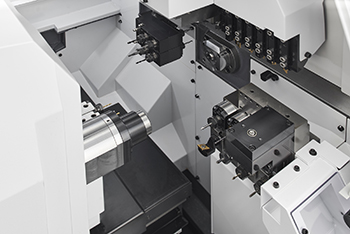

L12X model, inside the cutting room

2. Enhanced productivity with increased back spindle speed

By changing the back spindle drive system from a belt to a built-in motor, 12,000 min-1 of the maximum back spindle speed, an increase of up to 20% more than the existing VII type, is achieved. Also, we are improving productivity by shortening acceleration/deceleration time.

Main Machining Work

Precision instrument related parts, medical instrument parts, automobile-related parts, digital/IT related parts etc.

Machine Specifications

| Model Type | L12VIII | L12X | |

|---|---|---|---|

| Maximum Machining Diameter (D) | ø12mm | ||

| Maximum Machining Length (L) | Guide-bushing | 135mm/1chuck | |

| Guide-bushing-less | 30mm/1chuck | ||

| Maximum Drilling Diameter for Spindle | ø8mm | ||

| Maximum Tapping Diameter for Spindle | M6(Cut tap) | ||

| Maximum Drilling Diameter for Back Spindle | ø8mm | ||

| Maximum Tapping Diameter for Back Spindle | M6(Cut tap) | ||

| Maximum Drilling Diameter for Gang Rotary Tool | ø5mm | ||

| Maximum Tapping Diameter for Gang Rotary Tool | M4(Cut tap) | ||

| Number of Tools to be Mounted | Max.34 | Max.38 | |

| Spindle Speed | 15,000min-1 | ||

| Back Spindle Speed | 12,000min-1 | ||

| Gang Rotary Tool Spindle Speed | 10,000min-1 | ||

| Back Tool Spindle speed | 9,000min-1(OP) | 9,000min-1 | |

| Tool Size | Turning tool | ☐10(☐12) | |

| Sleeve | ø19.05mm | ||

| Spindle Motor | 2.2 / 3.7kW | ||

| Back Spindle Motor | 0.75 / 1.5kW | ||

| Rotary Gang Tool Spindle Motor | 0.75kW | ||

| Back Rotary Gang Tool Spindle Motor | 0.5kW(OP) | 0.5kW | |

| Rapid Feed rate | All axes 35m/min | Y2 axis 8m/min, other axes 35m/min | |

| Center Height | 1,050mm | ||

| Machine Height | 1,710mm | ||

| Required Floor Space | W1,840×D970mm | ||

| Machine Weight | 2,200kg | ||

- Maximum Machining Diameter (D)

- ø12mm

- Maximum Machining Length (L) "Guide-bushing"

- 135mm/1チャック

- Maximum Machining Length (L) "Guide-bushing-less"

- 30mm/1チャック

- Maximum Drilling Diameter for Spindle

- ø8mm

- Maximum Tapping Diameter for Spindle

- M6(Cut tap)

- Maximum Drilling Diameter for Back Spindle

- ø8mm

- Maximum Tapping Diameter for Back Spindle

- M6(Cut tap)

- Maximum Drilling Diameter for Gang Rotary Tool

- ø5mm

- Maximum Tapping Diameter for Gang Rotary Tool

- M4(Cut tap)

- Number of Tools to be Mounted

- Max.34

- Spindle Speed

- 15,000min-1

- Back Spindle Speed

- 12,000min-1

- Gang Rotary Tool Spindle Speed

- 10,000min-1

- Back Tool Spindle speed

- 9,000min-1(OP)

- Tool Size "Turning tool"

- ☐10(☐12)

- Tool Size "Sleeve"

- ø19.05mm

- Spindle Motor

- 2.2/3.7kW

- Back Spindle Motor

- 0.75/1.5kW

- Rotary Gang Tool Spindle Motor

- 0.75kW

- Back Rotary Gang Tool Spindle Motor

- 0.5kW(OP)

- Rapid Feed rate

- All axes 35m/min

- Center Height

- 1,050mm

- Machine Height

- 1,710mm

- Required Floor Space

- W1,840×D970mm

- Machine Weight

- 2,200kg

- Maximum Machining Diameter (D)

- ø12mm

- Maximum Machining Length (L) "Guide-bushing"

- 135mm/1チャック

- Maximum Machining Length (L) "Guide-bushing-less"

- 30mm/1チャック

- Maximum Drilling Diameter for Spindle

- ø8mm

- Maximum Tapping Diameter for Spindle

- M6(Cut tap)

- Maximum Drilling Diameter for Back Spindle

- ø8mm

- Maximum Tapping Diameter for Back Spindle

- M6(Cut tap)

- Maximum Drilling Diameter for Gang Rotary Tool

- ø5mm

- Maximum Tapping Diameter for Gang Rotary Tool

- M4(Cut tap)

- Number of Tools to be Mounted

- Max.38

- Spindle Speed

- 15,000min-1

- Back Spindle Speed

- 12,000min-1

- Gang Rotary Tool Spindle Speed

- 10,000min-1

- Back Tool Spindle speed

- 9,000min-1

- Tool Size "Turning tool"

- ☐10(☐12)

- Tool Size "Sleeve"

- ø19.05mm

- Spindle Motor

- 2.2/3.7kW

- Back Spindle Motor

- 0.75/1.5kW

- Rotary Gang Tool Spindle Motor

- 0.75kW

- Back Rotary Gang Tool Spindle Motor

- 0.5kW

- Rapid Feed rate

- Y2 axis 8m/min, other axes 35m/min

- Center Height

- 1,050mm

- Machine Height

- 1,710mm

- Required Floor Space

- W1,840×D970mm

- Machine Weight

- 2,200kg