Creating New Value through Combinations of Machines and Peripheral Units

Launch of “Total Solution” Models

Creating New Value through Combinations of Machines and Peripheral Units Launch of Total Solution Models

CITIZEN MACHINERY CO.,LTD.

CITIZEN MACHINERY CO., LTD. (Karuizawa Headquarters: Miyota-machi, Kitasaku-gun, Nagano-ken, President: Keiichi Nakajima) is launching total solution models that combine a variety of peripheral units such as robots, along with proprietary machining technologies, with CNC automatic lathes. These products will be exhibited at the 31st Japan International Machine Tool Fair (JIMTOF2022) to be held at the Tokyo Big Sight from November 8.

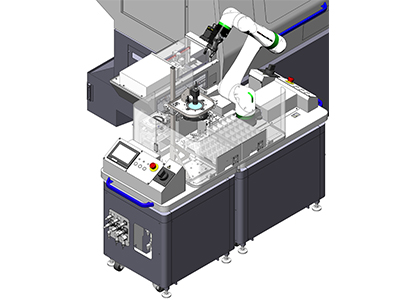

Cincom “L20XIIB5” + Collaborative Robot Advancing Automation and Labor Savings

The combination of Cincom’s top-of-the-range “L20XIIB5” model in the best-selling L20 Series with an “FA Friendly, On Cart Type”* new product utilizing a collaborative robot provides a more advanced automation system.

Automation is promoted before and during machining by optional functions on the machine including new solutions such as the “automatic chucking force adjustment function” and “chucking force display function”, which reduce setup times, in addition to the “ATC (automatic tool changer)”.Automation can be implemented in later processes after machining, including handling workpieces from the in-machine unloader (unit for taking workpieces out after machining) with a collaborative robot, and, after simple washing and air blowing, palletizing only good products through appearance inspections by image recognition with a camera equipped on the cart.These features enable quality control of the workpieces with complicated shapes that are unloaded from a sophisticated machine capable of complex machining.

- *

- A robot system where a robot and function modules are incorporated into the cart, compactly integrating later processes and realizing automation and labor savings.

“Cincom L20 XIIB5” Sliding Headstock Type Automatic CNC Lathe

FA Friendly, On Cart Type

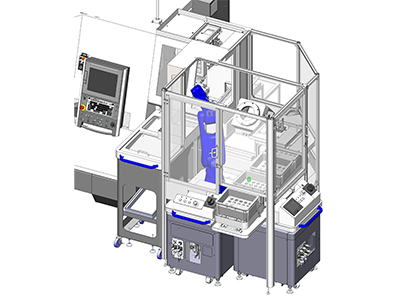

2.Productivity Improvement with Miyano “ANX42SYY” + Industrial Robot

A Miyano “ANX42SYY” equipped with our proprietary “LFV (low-frequency vibration cutting) technology” (optional) that substantially reduces machining stoppages due to chips has been combined with an “FA Friendly, On Cart Type” unit.

By adding an in-machine unloader as an option, workpieces unloaded from the unloader are handled by an industrial robot, and air blow, length measurement and palletizing are automated.This realizes product collection with zero dents and automated length measurement.Adopting an industrial robot for the FA Friendly function improves productivity while simultaneously achieving higher operating speeds and reduced costs.A tailstock that holds small-diameter long workpieces is also equipped as a new option, expanding the applicability.

“Miyano ANX42SYY” Fixed Headstock Type Automatic CNC Lathe

FA Friendly, On Cart Type

Citizen Machinery’s Total Solution

Up until now we have also been offering three-part solutions integrating “machines”, “IoT” and “skills that fully utilize the technology” under the "Ko No Ryosan" concept of simultaneously achieving individuality and mass production efficiency.From here on we will proceed to propose “new value” for each and every customer through total solutions that incorporate a wide range of solutions matched to the issues affecting particular products and customers, including “alkapplysolution”, which serves to improve customer productivity and increase working efficiency, the “CIToolingSystem”, which substantially shortens setup times and tool change times, and the “remnant bar reduction function using friction joining technology”, which helps to reduce environmental impact through energy savings, reduction of CO2 emissions and so on.

At JIMTOF 2022, we will exhibit 14 total solution models including the products described above.

Major Specifications

1.Cincom “L20XIIB5” Sliding Headstock Type Automatic CNC Lathe, Automation/Labor Savings Model

■ Main specifications of machine

| Model | L20ⅫB5 | |

|---|---|---|

| Max. machining diameter | ø20mm(ø25 oversized option) | |

| Max. machining length | GB Type | 200 mm per chucking |

| GBL Type | Max. 50 mm per chucking | |

| Spindle speed | Max.10,000min-1 | |

| Back spindle speed | Max.10,000min-1 | |

| Rapid feed rate | X1, Y1, Z1, X2, Z2 axis | 32m/min |

| Y2 axis | 8m/min | |

| Number of mountable tools | Max. 41 | |

| Tool size | Turning tool | □12mm(□13mm、□16mm) |

| Sleeve | ø19.05mm | |

| Motors | For spindle drive | 2.2/3.7/5.5kW |

| For back spindle drive | 1.5/2.2/3.7kW | |

| For driving front/back rotary tools | 0.75kW | |

| For coolant | 0.4kW | |

| Mass | 2,680kg | |

■ Main FA Friendly specifications

| Model | On Cart Type “cart equipped with collaborative robot” | |

|---|---|---|

| Applicable models | A20, L12, L20, L32, ANX42SYY, BNA Series, BNJ Series | |

| Equipped robot | Model | FANUC CRX-5iA |

| Reach | 994mm | |

| Degrees of freedom | 6 axes | |

| Equipped hand | ROBOTIQHAND-E | |

| Conveyable workpieces (maximum mass) | 2,000g | |

| Power capacity | 6.0KVA | |

| Rated voltage | Single phase 200 to 240 VAC (50/60 Hz) | |

| Installation method | Installation using the leveling pads provided | |

| User interface | Operation panel, teaching pendant | |

| Safety devices | Safety laser scanner, 2 units | |

| Size(Robot posture during transfer) | Width | 800mm |

| Depth | 580mm | |

| Height | 1450mm | |

| Mass | 300kg | |

| Model | On Cart Type (cart equipped with units) | |

|---|---|---|

| Applicable models | On Cart Type | |

| Equipped units | Simple washing, air blowing, image processing, storage | |

| Power capacity | 3.0 kVA | |

| Rated voltage | Single phase 200 to 240 VAC | |

| Installation method | Installation using the leveling pads provided | |

| User interface | Operation panel | |

| Size | Width | 670 mm |

| Depth | 580 mm | |

| Height | 1600 mm | |

| Mass | 310 kg | |

2.Miyano “ANX42SYY” Fixed Headstock Type Automatic CNC Lathe, Productivity Improvement Model

■ Main specifications of machine

| Model | ANX42SYY | |

|---|---|---|

| Max. machining diameter | ø42 mm | |

| Max. machining length | 130㎜ | |

| Spindle speed | Max.6,000min-1 | |

| Max. chucking diameter of back spindle | ø42 mm | |

| Back spindle speed | Max.6,000min-1 | |

| Axis strokes (feed distances) | X1 axis | 140 mm |

| Y1 axis | 70 mm (+35 mm/-35 mm) | |

| Z1 axis | 315 mm | |

| X2 axis | 140 mm | |

| Y2 axis | 70 mm(+35mm/-35mm) | |

| Z2 axis | 430 mm | |

| X3 axis | 240 mm (+120 mm/-120 mm) | |

| Z3 axis | 440 mm | |

| Number of tool mounting stations | Upper turret | 12 |

| Lower turret | 12 | |

| Tool size | Turning tool | □20 mm |

| Sleeve | ø25 mm | |

| Motors | For spindle drive | 11/7.5 kW |

| For back spindle drive | 11/7.5 kW | |

| For driving rotary tools on the upper turret | 2.2 kW | |

| For driving rotary tools on the lower turret | 2.2 kW | |

| Mass | 6,200 kg | |

■ Main FA Friendly specifications

| Model | On Cart Type “cart equipped with industrial robot” | |

|---|---|---|

| Applicable models | A20, L12, L20, L32, ANX42SYY, BNA Series, BNJ Series | |

| Equipped robot | Model | Yaskawa MOTOMAN-GP7 |

| Reach | 927 mm | |

| Degrees of freedom | 6 axes | |

| Equipped hand | SMCMHKL2-25 | |

| Conveyable workpieces (maximum mass) | 600 g | |

| Power capacity | 6.0 kVA | |

| Rated voltage | 3-phase 200 to 220 VAC (50/60 Hz) | |

| Installation method | Installation using the leveling pads provided | |

| User interface | Operation panel, teaching pendant | |

| Safety devices | Safety fence | |

| Size(Robot posture during transfer) | Width | 800 mm |

| Depth | 580 mm | |

| Height | 1650 mm | |

| Mass | 300 kg | |

| Model | On Cart Type (cart equipped with units) | |

|---|---|---|

| Applicable models | On Cart Type | |

| Equipped units | Air blow, length measurement, storage, pallet conveyor, fence | |

| Power capacity | 3.0 kVA | |

| Rated voltage | Single phase 200 to 240 VAC (50/60 Hz) | |

| Installation method | Installation using the leveling pads provided | |

| User interface | Operation panel | |

| Size | Width | 1220 mm |

| Depth | 1440 mm | |

| Height | 2000 mm | |

| Mass | 400 kg | |

About FA Friendly

This is a Citizen Machinery solution that addresses customers’ automation and labor savings needs.We will continue to expand our lineup of products that help to achieve FA in customers’ factories, which includes machines, devices and functions to achieve automation and labor savings on production lines, and in factories, which are aggregations of production lines.

About LFV (Low Frequency Vibration Cutting) Technology

The servo axes are vibrated in the direction of cutting in synchrony with spindle rotation using a control technology unique to Citizen, and this generates “air-cutting” time where the tool makes no contact during cutting to break up chips into smaller pieces.Besides substantially reducing machining stoppages due to chips and helping to improve customers’ productivity, it helps in reduction of environmental impacts including decreasing the CO2 emissions generated in the transportation of waste, since the chips are broken up into smaller pieces than those from conventional cutting and therefore occupy a smaller volume.

- *

- “LFV” is a registered trademark of Citizen Watch Co., Ltd.

About alkapplysolution

This is an aggregation of content that provides various solutions integrating the functions, technological knowhow built up by Citizen Machinery with ICT (Information and Communication Technology).A wide range of items have been arranged, including “alkartschool” which provides an opportunity to learn about NC programming, and “alkartlive 2”, a machine data collection tool that visualizes machine statuses and operating data.

About CIToolingSystem

A quick tool change system for tools with polygon taper shanks instead of conventional square shank tools.With a unique coupling structure, it secures repeatability of the tool nose position and improves rigidity during machining while substantially shortening setup and tool change times.

About the remnant bar reduction function using friction joining technology

Using the “friction joining technology” uniquely developed by Citizen, the remnant bar that is gripped by a friction-join clamping device (so that the material is held securely) is joined to the new bar that is supplied next, solving the problem of “remnant bars” that has been an issue for many years with sliding headstock type automatic lathes.

Overview of JIMTOF2022

- Exhibition period

- November 8 (Tue) to November 13 (Sun), 2022

- Location

- Tokyo Big Sight (Tokyo International Exhibition Center)

- Citizen Machinery’s exhibition booth number

- E5024

Contact

- CITIZEN MACHINERY CO., LTD. Corporate Planning Department

- +81-267-32-5911(Direct line)

- Citizen Watch Co., Ltd. Public & Investor Relations Department

- +81-42-466-1232 (Direct line)

- CITIZEN MACHINERY CO., LTD. Sales Division

- +81-267-32-5901 (Direct line)