The all-new Sliding Headstock Type CNC Automatic Lathe "L20 XIIB5", which is the highest-end machine equipped with a simultaneous 5-axis control function, will be added in the Cincom L20 series!

Citizen Machinery Co., Ltd.

Citizen Machinery Co., Ltd. (Headquarters: Miyota-machi, Kitasaku-gun, Nagano-ken, President: Keiichi Nakajima) adds the new top-of-the-line simultaneous 5-axis control function "Cincom L20 XIIB5" to the Cincom L20 series of sliding headstock type automatic lathes.

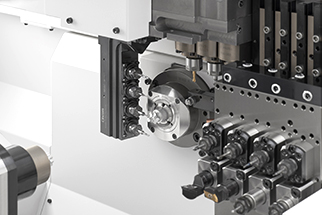

Introducing the top-of-the-line L20, a versatile best-selling machine for metalwork across a variety of industries. The previous simultaneous 4-axis control function L20 series now has the new addition L20 XIIB5, which supports simultaneous 5-axis control functionality.

The simultaneous 5-axis control function of the B-axis tool enables greater complex and highly accurate curved surface machining, making it possible to handle more complex workpieces in advanced fields such as medical care and aerospace. Additionally, the machining range of the front spindle that can be processed in one chuck has been expanded from a maximum of 90° to 110°. This feature can reduce the number of tools required on the back side, which contributes to shortening the setup and changeover time. In addition, this enables greater variety in the processing balance of the front and back.

A large 15-inch touch panel is used for the control panel, enabling greater intuitive operation (conventional models have an 8.4-inch panel).

A wide range of options, including the LFV (Low-frequency Vibration Cutting) function and the B-axis ATC (automatic tool changer) that featured in the L20 XII, further meets the needs of customers such as those in automation and stable production.

Main features

1.Improved basic performance by further development of the latest NC Device and mechanical equipment

The simultaneous 5-axis control function can be achieved thanks to installing the latest NC Device. The processing capacity of the program is also improved providing an even shorter cycle time. The optional LFV function that can be used on the front and back helps to eliminate chip issues, and by improving the cutting oil tank, continuous operation over longer periods is possible, improving productivity and stable production compared to conventional machines.

2.Greater intuitive operation is achievable thanks to a renewed control panel

A large 15-inch touch panel is used for the control panel, enabling further intuitive operation with an HMI based on a universal design. By adopting a cutting room door that can be fully opened, and installing a door on the back of the machine, it is easier to access the cutting room such as for tool setting, and operability and workability have also been improved.

3.Wide option range

We also offer an abundant range of options to realize the optimum specification for each customer requirement. These include various functions such as a loader/unloader device, a B-axis ATC, an LFV that can be used on the front and back, and IoT friendly and FA friendly functions. These are all available on-site at your factory, contributing to greater automation and labor saving.

Main machining work

Precision equipment parts, medical instrument parts, electronic equipment parts, automobile-related parts, etc.

Machine Specifications

| Item | L20 XIIB5 | |

|---|---|---|

| Maximum machining diameter | ø20mm(ø25Oversize Option) | |

| Maximum machining length | GB machine | 200mm/chuck |

| GBL machine | Workpiece diameterx2.5/chuck | |

| Spindle speed | Max.10,000min-1 | |

| Maximum chuck diameter of back spindle | ø20mm(ø25Oversize Option) | |

| Back spindle speed | Max.10,000min-1 | |

| Rapid feed rate | X1 axis | 32m/min |

| Y1 axis | 32m/min | |

| Z1 axis | 32m/min | |

| X2 axis | 32m/min | |

| Y2 axis | 8m/min | |

| Z2 axis | 32m/min | |

| Number of tools to be mounted | Max.41 | |

| Tool size | Turning tool | □12mm(□13mm,Cut-off tool □16mm) |

| Motors | For spindle drive | 2.2/3.7/5.5kW |

| For tool spindle drive(gang rotary tool post) | 1.0kW(Option 2.2kW) | |

| For back spindle drive | 1.5/2.2/3.7kW | |

| For rotary tool drive of Back tool post | 0.75kW | |

| for rotary tool drive of the opposed tool post | 0.75kW | |

| Weight | 2,680kg | |

- Maximum machining diameter

- ø20mm(ø25Oversize Option)

- Maximum machining length [GB machine]

- 200mm/chuck

- Maximum machining length [GBL machine]

- Workpiece diameterx2.5/chuck

- Spindle speed

- Max.10,000min-1

- Maximum chuck diameter of back spindle

- ø20mm(ø25Oversize Option)

- Back spindle speed

- Max.10,000min-1

- Rapid feed rate [X1 axis]

- 32m/min-1

- Rapid feed rate [Y1 axis]

- 32m/min-1

- Rapid feed rate [Z1 axis]

- 32m/min-1

- Rapid feed rate [X2 axis]

- 32m/min-1

- Rapid feed rate [Y2 axis]

- 8m/min-1

- Rapid feed rate [Z2 axis]

- 32m/min-1

- Number of tools to be mounted

- Max.41

- Tool size [Turning tool]

- □12mm(□13mm,Cut-off tool □16mm)

- Motors [For spindle drive]

- 2.2/3.7/5.5kW

- Motors [For tool spindle drive(gang rotary tool post)]

- 1.0kW(Option 2.2kW)

- Motors [For back spindle drive]

- 1.5/2.2/3.7kW

- Motors [For rotary tool drive of Back tool post]

- 0.75kW

- Motors [for rotary tool drive of the opposed tool post]

- 0.75kW

- Weight

- 2,680kg