Launch of the new Cincom "M32" products

- Improvement in combined machining performance and productivity with Cincom's high-end M series -

Citizen Machinery Co., Ltd.

Citizen Machinery Co., Ltd. (Headquarters: Miyota-machi, Kitasaku-gun, Nagano Prefecture; President: Keiichi Nakajima) will release three new models of its sliding headstock type automatic CNC lathe Cincom "M32".

The new products will be exhibited at "IMTS 2018," the largest machining tool trade fair in the Americas to be held in Chicago, USA from September 10th, and "JIMTOF 2018" to be held from November 1st.

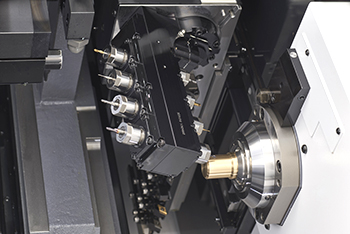

While continuing the unique "Gang tool + Turret" configuration that the M series is known for, the new product is redesigned from the base bed up for a full model change.

Productivity has been improved by installing a single drive for the turret rotary tool, increasing the output power of each motor in the front and back spindles to be upwards of 1.5 to 2 times that of existing models, and incorporating the latest NC devices. It is also equipped with a newly developed HMI (Human Machine Interface) operation panel. The doors of the machining area have been made larger, providing bigger work space, and thereby improving operability and usability.

In the high-end model of VIII type, complex and combined machining is enabled by mounting the Y axis on the back tool post and the B axis on the gang rotary tool. The B axis can also handle machining for the back spindle, which increases the flexibility of machining at the back spindle, improving the distribution of the machining process which otherwise tends to be biased towards the front spindle, and improves productivity.

Cincom M32

Main Features

1. Standard equipment that supports high productivity

For the front / back spindles, the output is increased by 1.5 to 2 times compared to existing machines, the maximum torque of the turret rotary tool motor is also more than doubled, making heavy machining possible with high productivity. In addition, for the first time, a Cincom machine comes with a single drive turret for driving only the selected rotary tool. A number of features are improved, including the precise power transmission for toolings, high efficiency / high accuracy, and high durability of the toolings.

The main spindle switching function is equipped as a standard for the first time in M series, which allows to switch between two types: a guide-bushing type*1 suitable for machining of longer workpieces, and a guide-bushing-less type suitable for shorter remnant length. By matching the features of each type with the processing conditions, we will contribute to the reduction of total running costs of our customers.

2. Combined machining is realized by the B axis with improved functions (VIII type only)

The B axis (VIII type only) is the slant axis in reference to the Y axis, which enables various diagonal machining, such as slant machining with multiple angles and helical interpolation machining. Machining on the back spindle side is also possible with the angle range of 150°, which increases the flexibility in processing. Even NC programs for slant machining that tend to be difficult are made easy to set up.

The contouring machining function with simultaneous 5-axis control (three orthogonal axes and two rotational axes) makes it possible to finish a cutting surface cleanly even on curved surfaces because it allows machining with continuously optimum angles.

3. Operator friendly

The operation panel is equipped with a new HMI (Human Machine Interface) and features a 15-inch touch panel adopted to improve ease-of-use for the operator, enabling faster tool set selection by selecting the turret tooling type at the operation setting screen, which reduces programming and setup times.

Newly introduced universal design for color arrangement on the new control panel.*2 Through consideration of the diversity about how colors appear to each person, we are able to provide easy-to-view and easy-to-understand information to everyone.

We extended the glass area by 65% over existing models so that the cutting point can be seen even when the doors of the machining area are closed. In addition, we have targeted improved usability by designing a wide and open work space, facilitating installation of tools by the operator, etc.

- *1

- Guide bushing: A device that supports the material near the tool so that the material does not bend when cutting an elongated workpiece. In the case of short workpiece machining, the guide bush is unnecessary and extra material (remnant material) between the guide bushing and the chuck can be reduced.

- *2

- We have obtained certification from the Media Universal Design (MUD) Association.

Main applications of machining work

Medical equipment parts, automotive parts, hydro-pneumatic equipment parts, precision equipment parts, etc

Machine specification

| Model | M32V | M32VII | M32VIII | |

|---|---|---|---|---|

| Maximum machining diameter | ø32mm | |||

| Maximum machining length | Guide bushing | 320mm | ||

| Guide bushing-less | 2.5D(80mm) | |||

| Maximum front drilling diameter | ø12mm | |||

| Maximum front tapping diameter (cutting tap) | M12 | |||

| Spindle speed | Max.8,000min-1 | |||

| Maxunyn chuck diameter of the back spindle | ø32mm | |||

| Maximum finished product length of the back spindle | 145mm | |||

| Maximum drilling diameter in back machining | ø12mm | |||

| Maximum tapping diameter in back machining (cutting tap) | M12 | |||

| Back spindle speed | Max.8,000min-1 | |||

| Rotary tool maximum drilling diameter | Gang tool post | ø8mm | ||

| Turret | ø12mm | |||

| Back tool post | - | ø8mm | ||

| Rotary tool maximum tapping diameter (cutting tap) | Gang tool post | M6 | ||

| Turret | M12 | |||

| Back tool post | - | M6 | ||

| Spindle speed | Gang tool post | Max.9,000min-1 | ||

| Turret | Max.6,000min-1 | |||

| Back tool post | - | Max.6,000min-1 | ||

| Tool Capacity | Max 36 | Max 40 | Max 36 | |

| Tool size | Turning tool | □16mm | ||

| Sleeve | ø25.4mm | |||

| Motor | For spindle drive | 5.5/7.5kW | ||

| For back spindle drive | 5.5/7.5kW | |||

| For tool spindle drive (gang tool post) | 2.2kW | |||

| For turret rotary tool drive | 2.2kW | |||

| For tool spindle drive (back turret post) | - | 1.0kW | ||

| Weight | 4,250kg | 4,300kg | ||

- Maximum machining diameter

- ø32mm

- Maximum machining length [Guide bushing]

- 320mm

- Maximum machining length [Guide bushing-less]

- 2.5D(80mm)

- Maximum front drilling diameter

- ø12mm

- Maximum front tapping diameter (cutting tap)

- M12

- Spindle speed

- Max.8,000min-1

- Maxunyn chuck diameter of the back spindle

- ø32mm

- Maximum finished product length of the back spindle

- 145mm

- Maximum drilling diameter in back machining

- ø12mm

- Maximum tapping diameter in back machining (cutting tap)

- M12

- Back spindle speed

- Max.8,000min-1

- Rotary tool maximum drilling diameter [Gang tool post]

- ø8mm

- Rotary tool maximum drilling diameter [Turret]

- ø12mm

- Rotary tool maximum drilling diameter [Back tool post]

- -

- Rotary tool maximum tapping diameter (cutting tap) [Gang tool post]

- M6

- Rotary tool maximum tapping diameter (cutting tap) [Turret]

- M12

- Rotary tool maximum tapping diameter (cutting tap) [Back tool post]

- -

- Spindle speed [Gang tool post]

- Max.9,000min-1

- Spindle speed [Turret]

- Max.6,000min-1

- Spindle speed [Back tool post]

- -

- Tool Capacity

- Max 36

- Tool size [Turning tool]

- □16mm

- Tool size [Sleeve]

- ø25.4mm

- Motor [For spindle drive]

- 5.5/7.5kW

- Motor [For back spindle drive]

- 5.5/7.5kW

- Motor [For tool spindle drive (gang tool post)]

- 2.2kW

- Motor [For turret rotary tool drive]

- 2.2kW

- Motor [For tool spindle drive (back turret post)]

- -

- Weight

- 4,250kg

- Maximum machining diameter

- ø32mm

- Maximum machining length [Guide bushing]

- 320mm

- Maximum machining length [Guide bushing-less]

- 2.5D(80mm)

- Maximum front drilling diameter

- ø12mm

- Maximum front tapping diameter (cutting tap)

- M12

- Spindle speed

- Max.8,000min-1

- Maxunyn chuck diameter of the back spindle

- ø32mm

- Maximum finished product length of the back spindle

- 145mm

- Maximum drilling diameter in back machining

- ø12mm

- Maximum tapping diameter in back machining (cutting tap)

- M12

- Back spindle speed

- Max.8,000min-1

- Rotary tool maximum drilling diameter [Gang tool post]

- ø8mm

- Rotary tool maximum drilling diameter [Turret]

- ø12mm

- Rotary tool maximum drilling diameter [Back tool post]

- ø8mm

- Rotary tool maximum tapping diameter (cutting tap) [Gang tool post]

- M6

- Rotary tool maximum tapping diameter (cutting tap) [Turret]

- M12

- Rotary tool maximum tapping diameter (cutting tap) [Back tool post]

- M6

- Spindle speed [Gang tool post]

- Max.9,000min-1

- Spindle speed [Turret]

- Max.6,000min-1

- Spindle speed [Back tool post]

- Max.6,000min-1

- Tool Capacity

- Max 40

- Tool size [Turning tool]

- □16mm

- Tool size [Sleeve]

- ø25.4mm

- Motor [For spindle drive]

- 5.5/7.5kW

- Motor [For back spindle drive]

- 5.5/7.5kW

- Motor [For tool spindle drive (gang tool post)]

- 2.2kW

- Motor [For turret rotary tool drive]

- 2.2kW

- Motor [For tool spindle drive (back turret post)]

- 1.0kW

- Weight

- 4,300kg

- Maximum machining diameter

- ø32mm

- Maximum machining length [Guide bushing]

- 320mm

- Maximum machining length [Guide bushing-less]

- 2.5D(80mm)

- Maximum front drilling diameter

- ø12mm

- Maximum front tapping diameter (cutting tap)

- M12

- Spindle speed

- Max.8,000min-1

- Maxunyn chuck diameter of the back spindle

- ø32mm

- Maximum finished product length of the back spindle

- 145mm

- Maximum drilling diameter in back machining

- ø12mm

- Maximum tapping diameter in back machining (cutting tap)

- M12

- Back spindle speed

- Max.8,000min-1

- Rotary tool maximum drilling diameter [Gang tool post]

- ø8mm

- Rotary tool maximum drilling diameter [Turret]

- ø12mm

- Rotary tool maximum drilling diameter [Back tool post]

- ø8mm

- Rotary tool maximum tapping diameter (cutting tap) [Gang tool post]

- M6

- Rotary tool maximum tapping diameter (cutting tap) [Turret]

- M12

- Rotary tool maximum tapping diameter (cutting tap) [Back tool post]

- M6

- Spindle speed [Gang tool post]

- Max.9,000min-1

- Spindle speed [Turret]

- Max.6,000min-1

- Spindle speed [Back tool post]

- Max.6,000min-1

- Tool Capacity

- Max 36

- Tool size [Turning tool]

- □16mm

- Tool size [Sleeve]

- ø25.4mm

- Motor [For spindle drive]

- 5.5/7.5kW

- Motor [For back spindle drive]

- 5.5/7.5kW

- Motor [For tool spindle drive (gang tool post)]

- 2.2kW

- Motor [For turret rotary tool drive]

- 2.2kW

- Motor [For tool spindle drive (back turret post)]

- 1.0kW

- Weight

- 4,300kg