Miyano "BNA42 Series" New Model Releases

- New models with turrets fitted with Y axis functionality -

Citizen Machinery Co., Ltd.

Citizen Machinery Co., Ltd. (Headquarters: Miyota-machi, Kitasaku-gun, Nagano-ken, President: Keiichi Nakajima) will be adding fixed headstock type CNC automatic lathes "BNA42SY" and "BNA42CY" to its "BNA42" series.

The new products will be exhibited at "JIMTOF2018" in Tokyo Big Sight starting on 1 November.

To meet increasing needs for combined device performing a series of machining, the "BNA42SY" with two spindles and one turret providing high basic performance and user-friendliness, and the "BNA42CY" with one spindle and one turret, facilitating chucker specifications for the machining of casting and forging materials, have been added to the Miyano lineup.

Number of turret tool mounting faces is increased from 8 to 12. In addition, Y axis is added to enable combined machining. Furthermore, the rigidity is improved by redesigning the bed (base) and turret, enabling further high-power/combined processing.

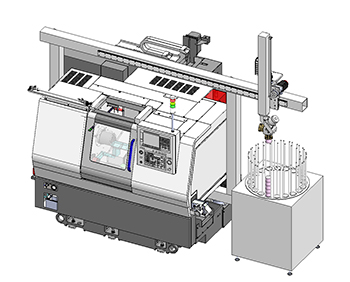

The mounting base for the legs of the gantry loader which holds and moves the workpiece (parts), and the loader interface for the chucker facilitate easy installation by third-party operators.

Main Features

1. Y-axis functionality is added to the turret, and the number of tool mounting faces is now 1.5 times (compared to existing Miyano products)

The number of turret tool mounting faces is now 12, 1.5 times the number of conventional machines, and the Y axis is added to enable further combined machining.

High rigidity has been achieved by a new design for the bed and the turret. For the new bed, the chip conveyor (discharger) can be positioned to right or back side of the machine based on the floor layout.

2. Utilizing the latest NC device reduces acceleration/deceleration time for the spindle by 20% (compared to existing Miyano products)

Utilizing the latest NC device rises the power output of the spindle amplifier. This achieves reduction in acceleration/deceleration time for the spindle by 20% compared to existing Miyano products, realizing shorter cycle time and an improved productivity.

Control panel is changed from 8.4-inch display to 10.4-inch display, improving its visibility. In addition, the device is not only compatible with the programs of conventional machines, but also facilitates easy programming for superposition machining.

3. Machining of bars & casting and forging materials enabled (BNA42CY)

By selecting either collet or power chucks, machining of bars, and casting and forging materials are enabled, appropriately meeting the client's demand.

Chucker specifications for machining casting and forging materials are installed with a loader interface and gantry leg mounting base on the left and right sides of the bed, providing flexibility for loader mounting.

Sufficient space is secured for the upper part of the spindle, allowing loader hand insertion.

Main Machining Work

Automobile-related parts, hydraulic/pneumatic instrument parts, and medical instrument parts, etc.

Machine Specifications

| Model Type | BNA42CY | BNA42SY | |

|---|---|---|---|

| Maximum Machining Diameter | ø42mm | ||

| Maximum Machining Length | 200mm | 100mm | |

| Spindle Speed | Max.6,000min-1 | ||

| Back Side Spindle Maximum Chuck Diameter | - | ø42mm | |

| Back spindle speed | - | Max.5,000min-1 | |

| Turret Tool Mounting Faces | 12st. | ||

| Tool Size | Turning tool | ☐20mm | |

| Sleeve | ø25mm | ||

| NC Device | FANUC Oi-TF PLUS 10.4" Monitor | ||

| Motors | For Spindle Drive | 5.5 / 7.5 / 11kW | |

| For Back Spindle Drive | - | 3.7 / 5.5kW | |

| For Turret Tools Spindle Drive | 1 / 2.8kW | ||

| Machine Weight | 3,430kg | 3,880kg | |

- Maximum Machining Diameter

- ø42mm

- Maximum Machining Length

- 200mm

- Spindle Speed

- Max.6,000min-1

- Back Side Spindle Maximum Chuck Diameter

- -

- Back spindle speed

- -

- Turret Tool Mounting Faces

- 12st.

- Tool Size "Turning tool"

- ☐20mm

- Tool Size "Sleeve"

- ø25mm

- NC Device

- FANUC Oi-TF PLUS 10.4" Monitor

- Motors "For Spindle Drive"

- 5.5/7.5/11kW

- Motors "For Back Spindle Drive"

- -

- Motors "For Turret Tools Spindle Drive"

- 1/2.8kW

- Machine Weight

- 3,430kg

- Maximum Machining Diameter

- ø42mm

- Maximum Machining Length

- 100mm

- Spindle Speed

- Max.6,000min-1

- Back Side Spindle Maximum Chuck Diameter

- ø42mm

- Back spindle speed

- Max.5,000min-1

- Turret Tool Mounting Faces

- 12st.

- Tool Size "Turning tool"

- ☐20mm

- Tool Size "Sleeve"

- ø25mm

- NC Device

- FANUC Oi-TF PLUS 10.4" Monitor

- Motors "For Spindle Drive"

- 5.5/7.5/11kW

- Motors "For Back Spindle Drive"

- 3.7/5.5kW

- Motors "For Turret Tools Spindle Drive"

- 1/2.8kW

- Machine Weight

- 3,880kg