Citizen Machinery has the solutions to meet the automation and labor-reduction needs of our customers' production sites.

By integrating our accumulated automation know-how with FA Friendly, we can offer optimal products for factory automation to solve issues at production sites, such as workpiece supply, outloading, and storage.

This machine offers a new level of automation and labor reduction by extending the scope of what can be "automated" on the front and rear processes of automatic lathing.

List of products exhibited

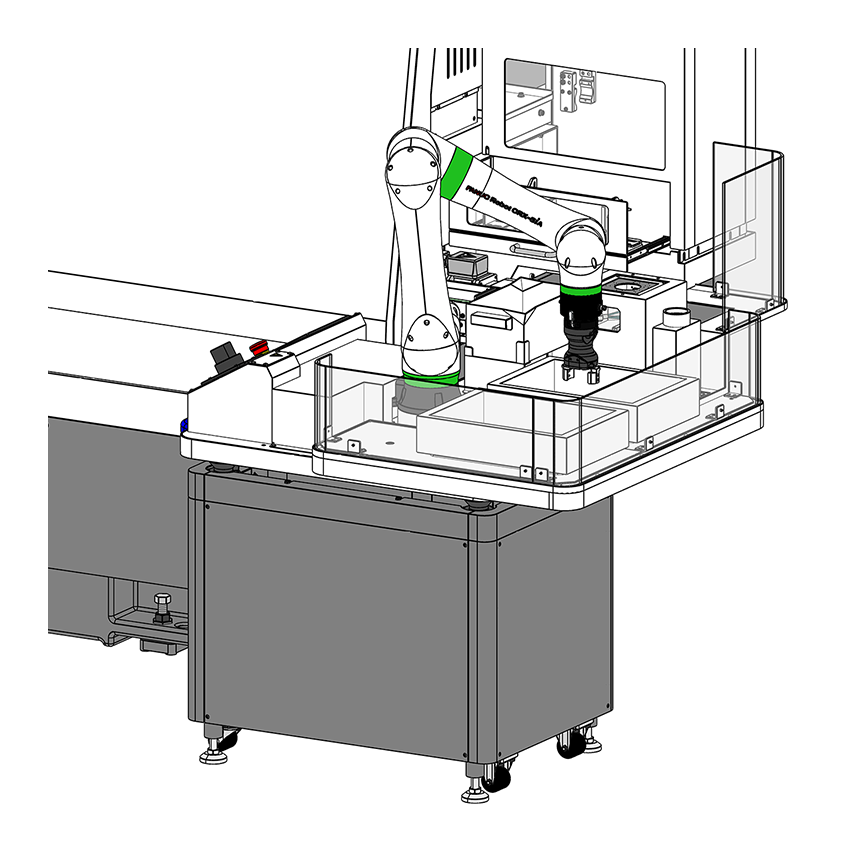

On-cart type

- BNX51MSY+On-cart type

-

Machined workpieces are taken out of the machine by an outloader, and a robot picks up the workpieces placed on the product tray to automatically perform the post-processing steps on the cart.

This contributes to enhanced automation by minimizing dents and scratches caused by handling.

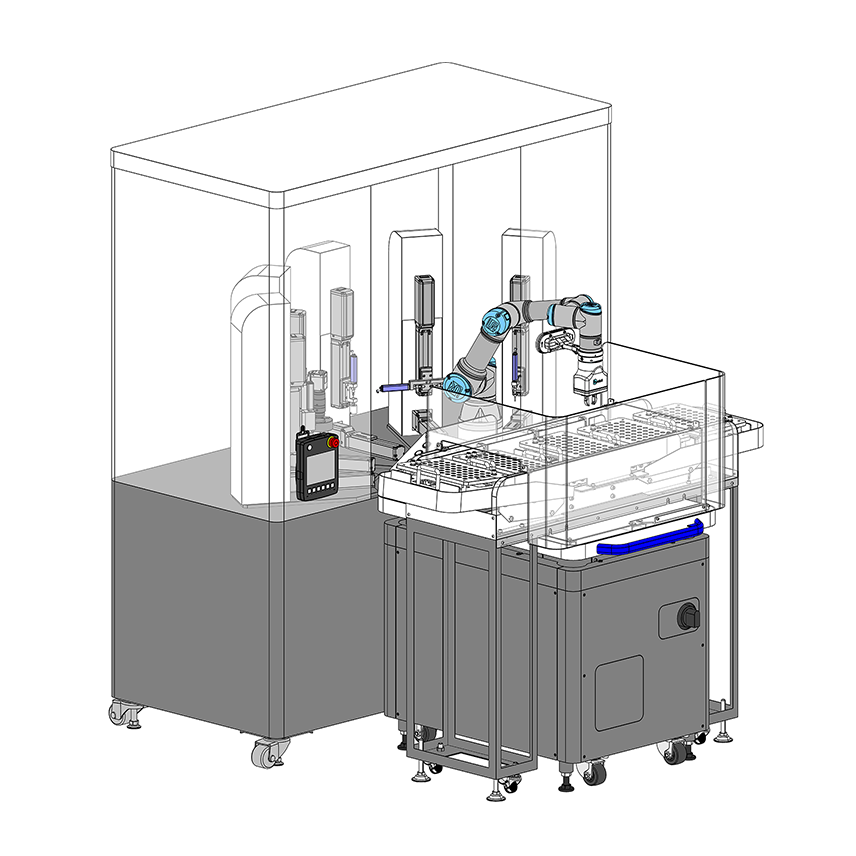

- Measuring Cell (Docking Design)

-

This automatic inspection system measures the outer and inner diameters of workpieces stored on pallets.

This system can be equipped with up to five different measuring station modules, allowing you to create a customized system suited to your specific needs.

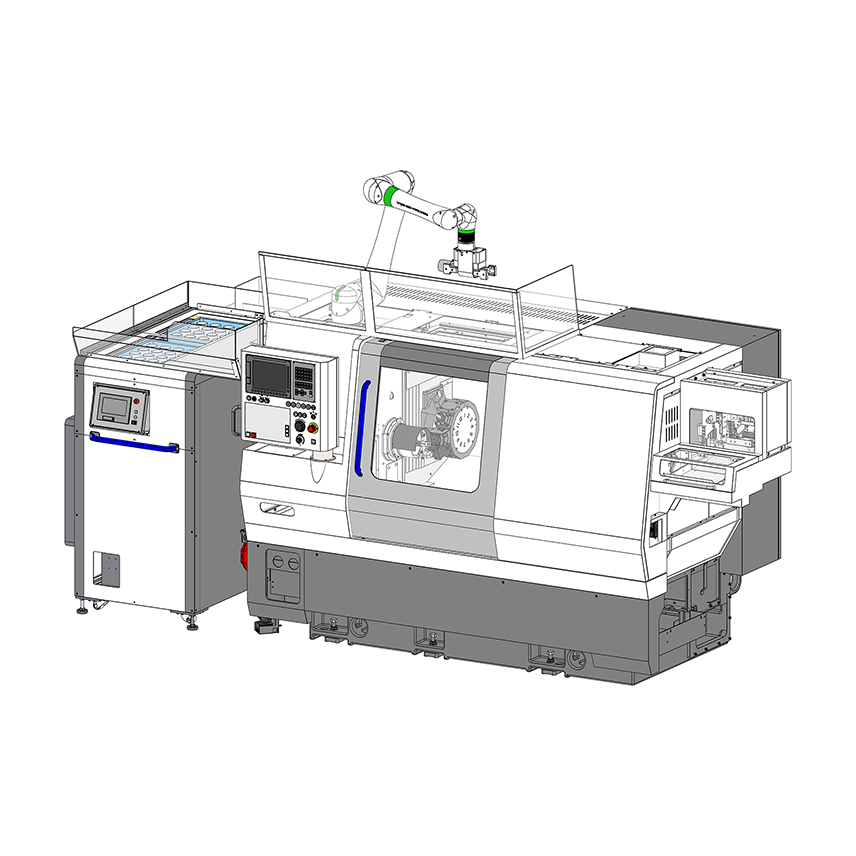

On-machine type

- BNJ51SY+On-machine type

- Mounting a robot on the machine enables it to be used as an opposed spindle-type combined chucker capable of supplying materials as well as aligning and storing workpieces. Combined with a pallet changer, this machine contributes to labor reduction and increased productivity.

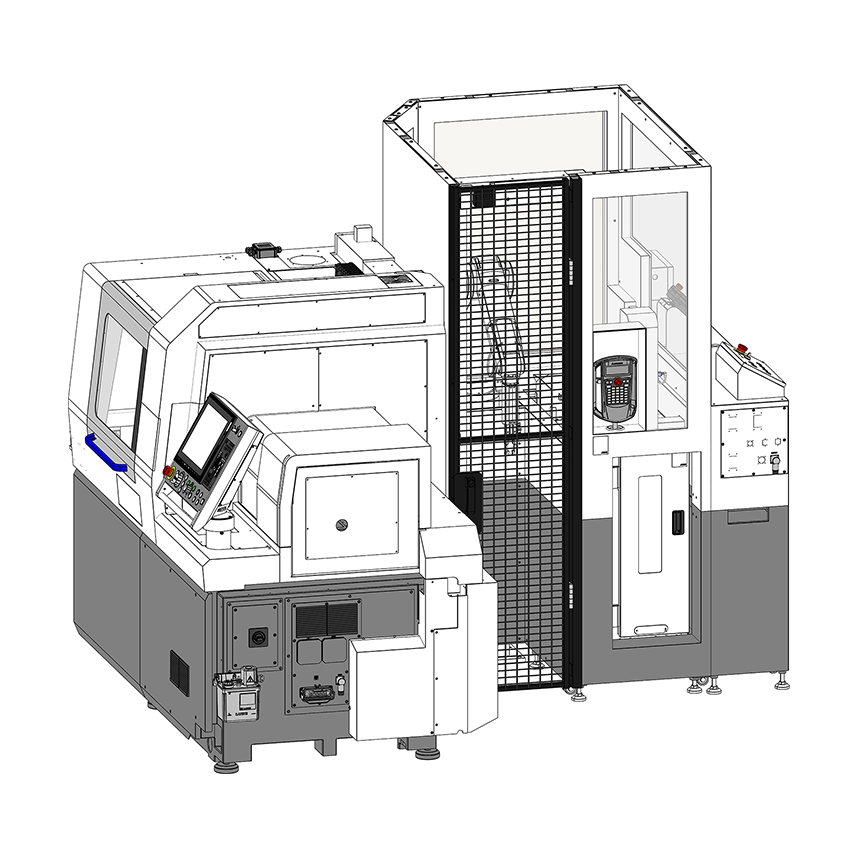

Side-entry type

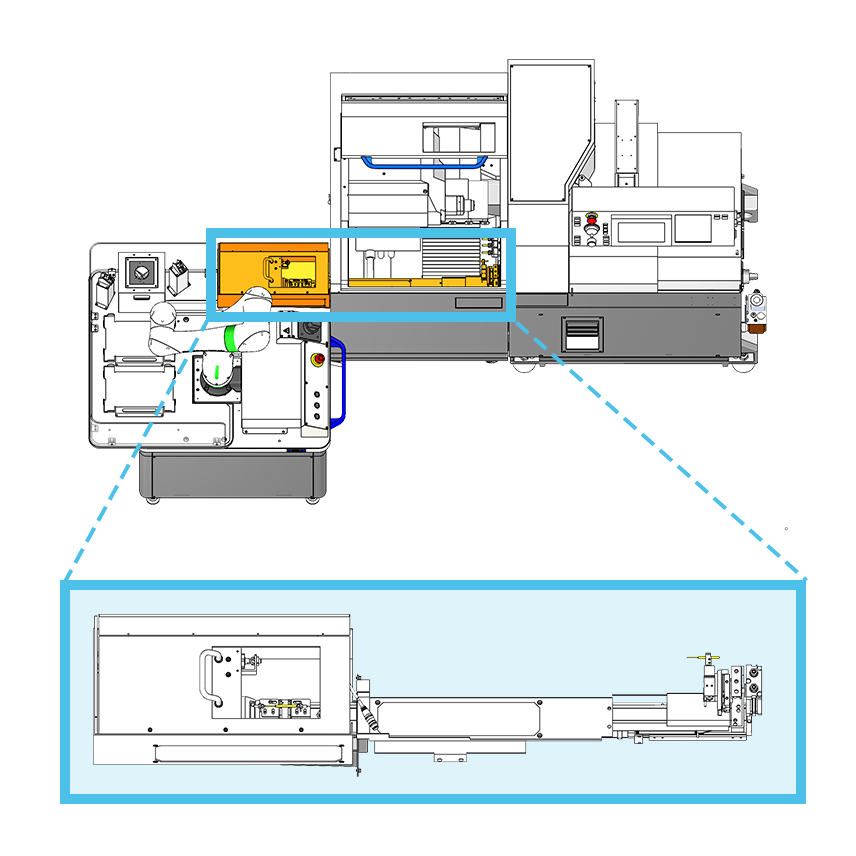

- L20X + Side-entry type

- This automated device consists of multiple post-processing units on the back of the machine. A robot enters the machining chamber and collects workpieces directly from the rear spindle. After the workpieces are collected, they are simply cleaned, air-blown, and their outer diameter is measured, and only the non-defective ones are stored on pallets.

L12 Product Outloader (Shuttle)

- L12 Product Outloader (Shuttle)+ On-cart type

- Workpieces are collected from the rear spindle by a hand inside the machine and placed on a product tray on the shuttle. Workpieces placed on the product tray can then be taken out of the machine while maintaining their position. This machine can also connect to an on-cart type, allowing for even smoother post-machining automation.